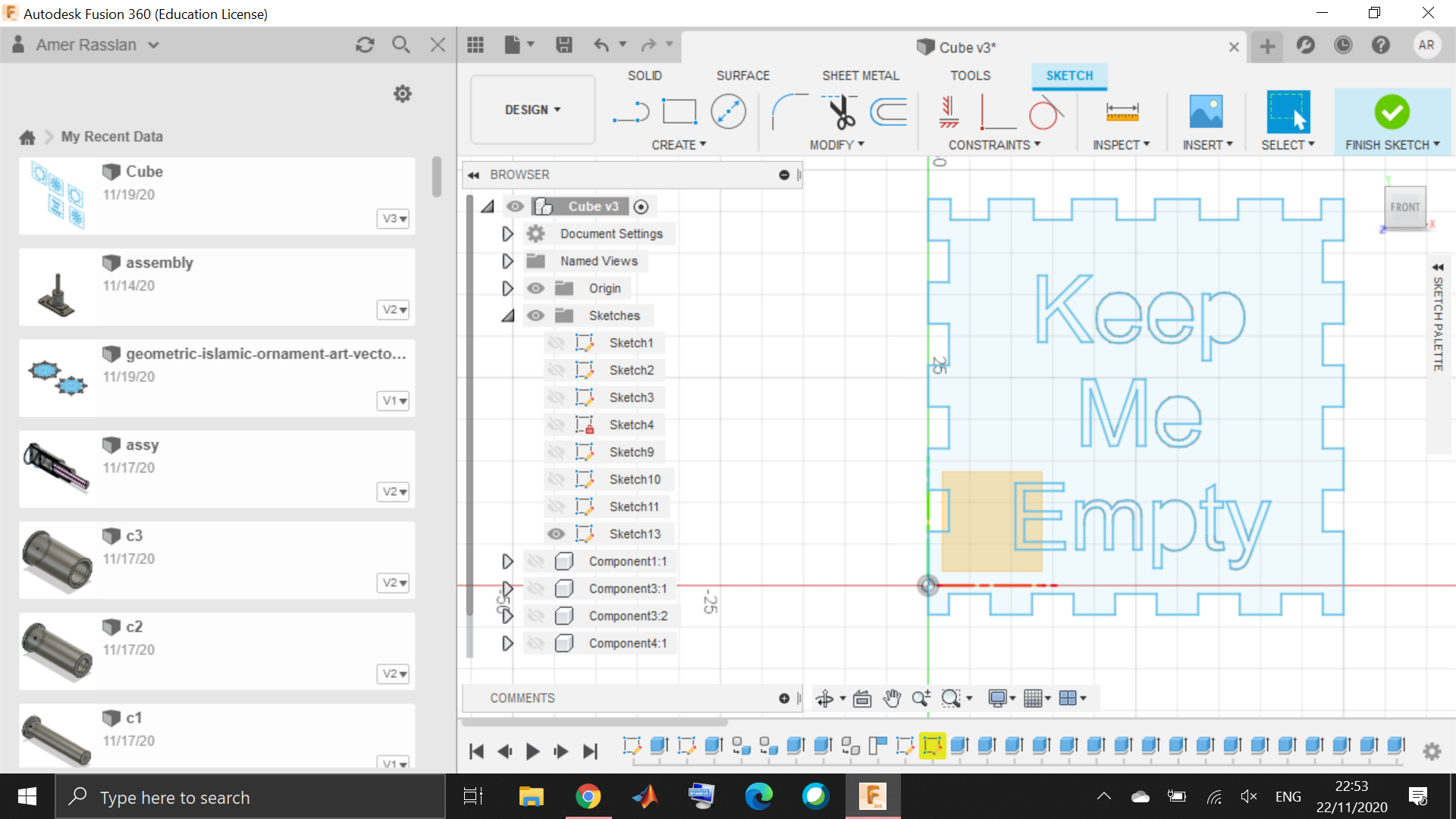

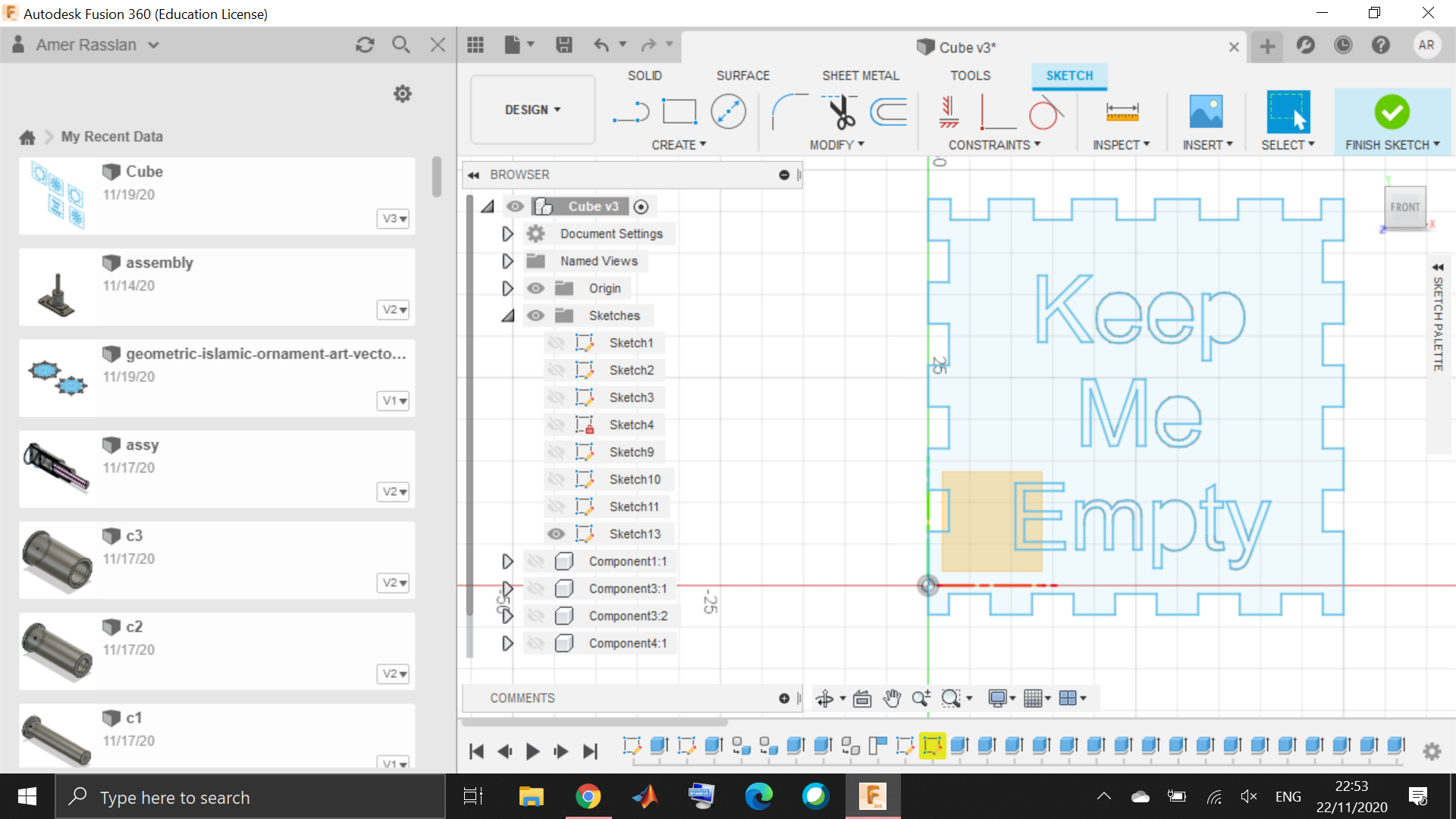

Here is an example of a design for laser cutting technology using the program fusion 360

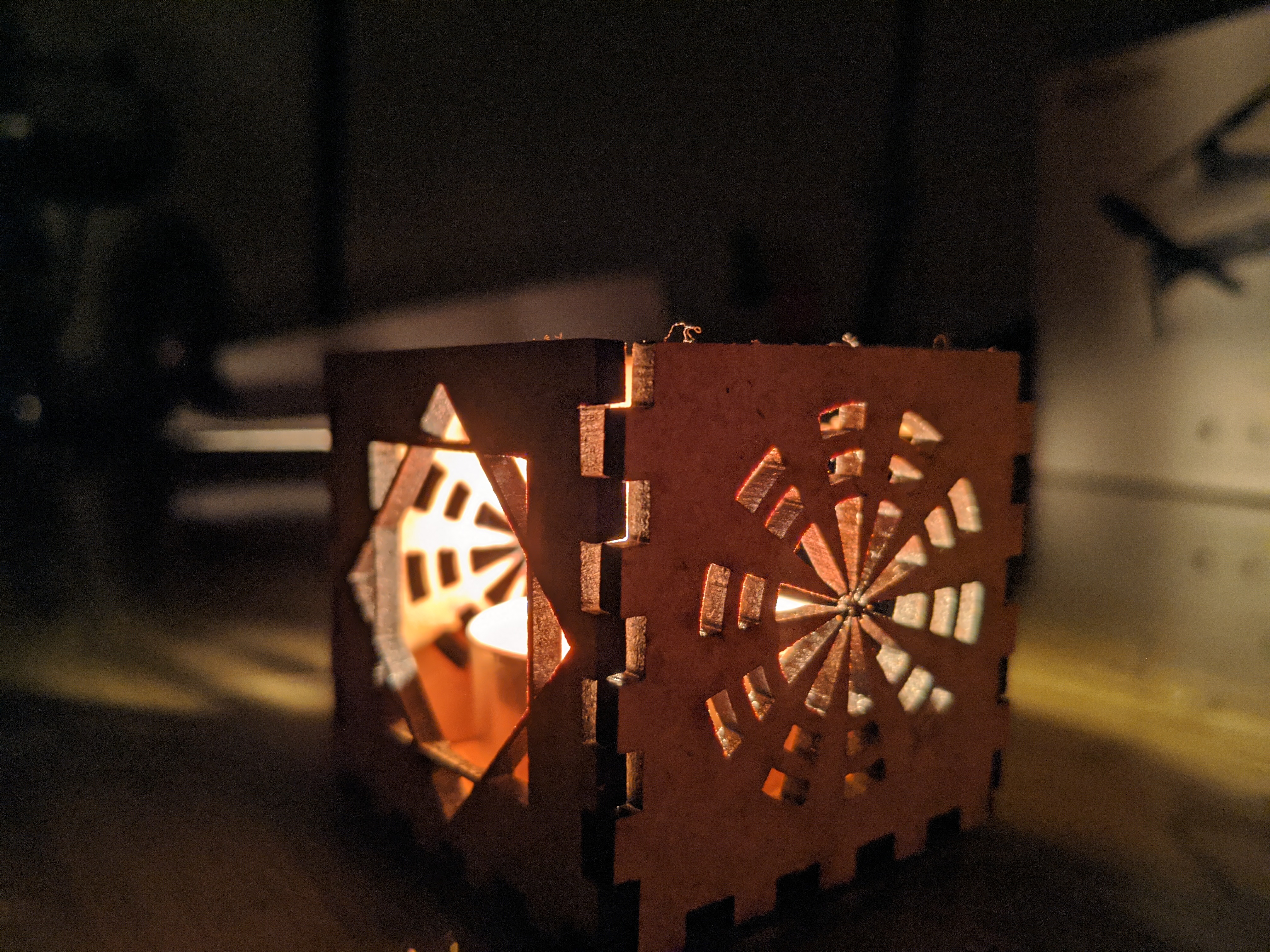

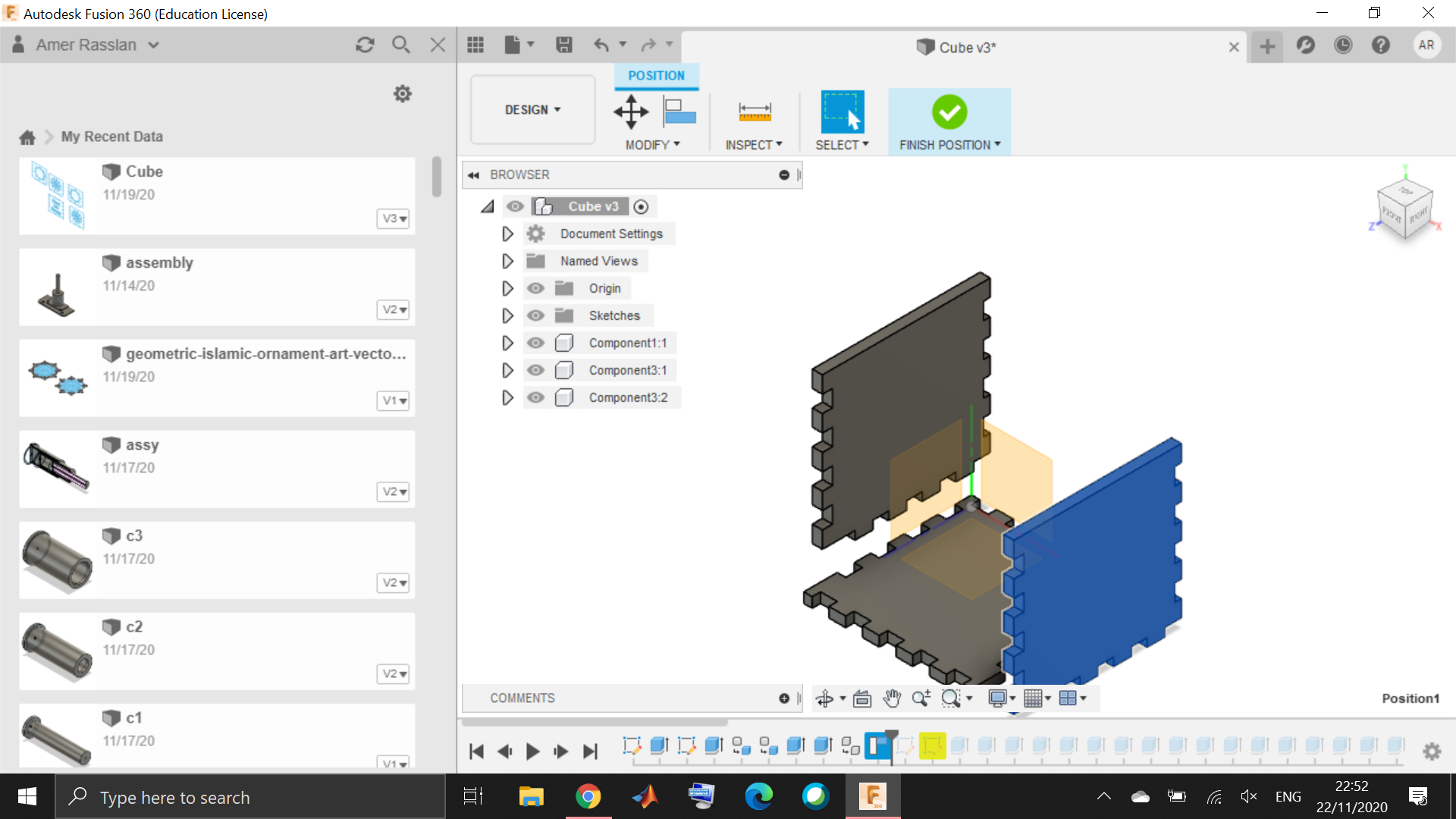

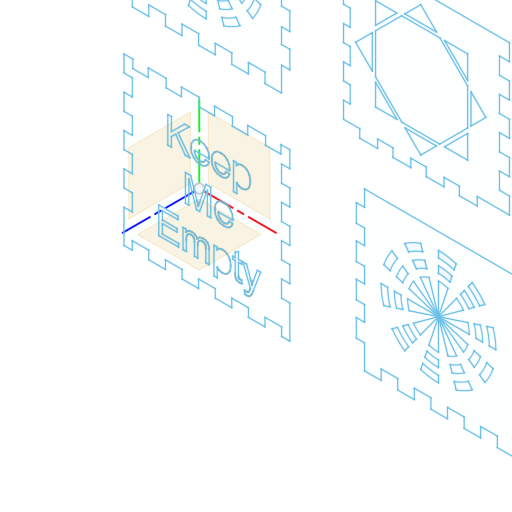

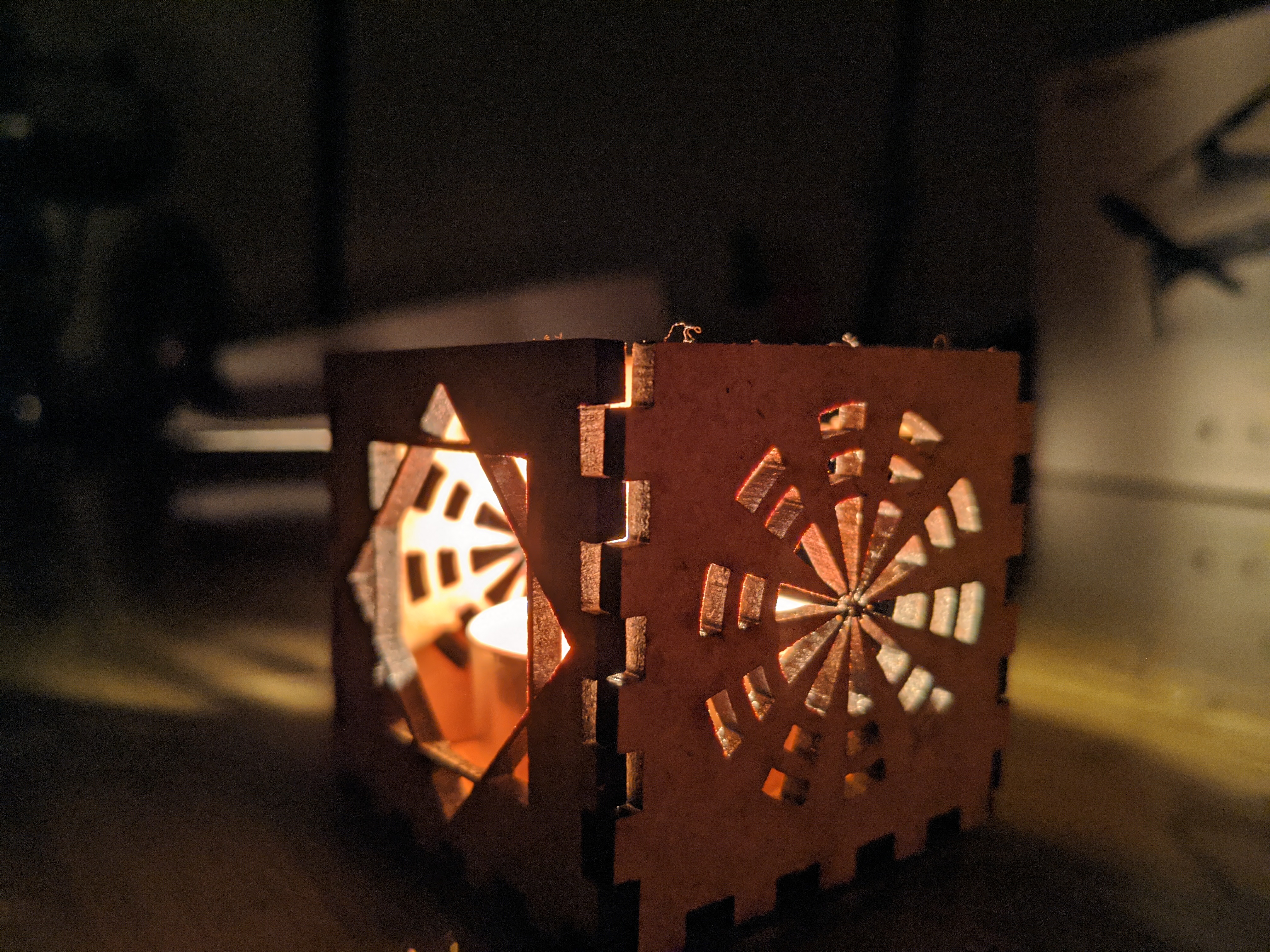

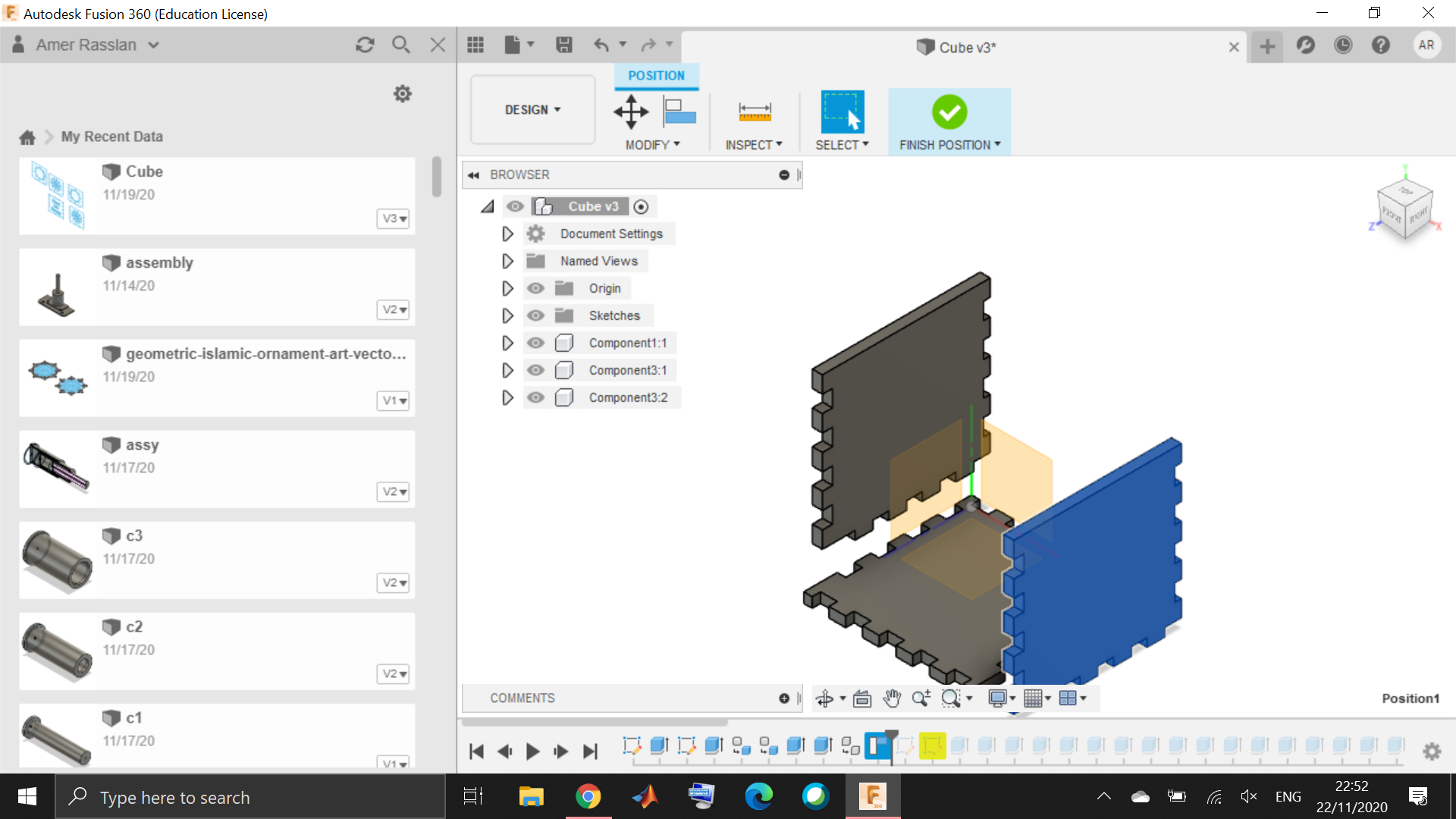

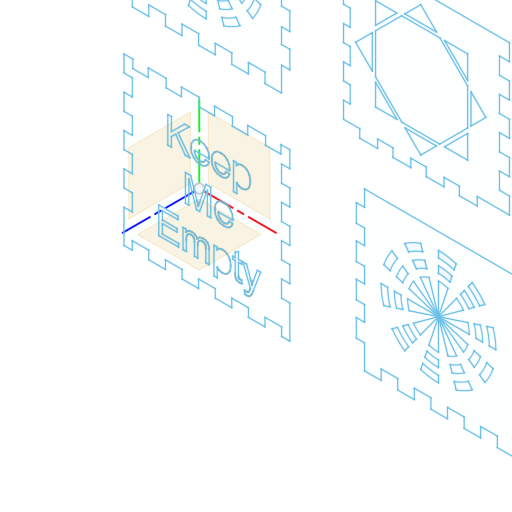

the final design should look like this which is a cube works as a candle holder

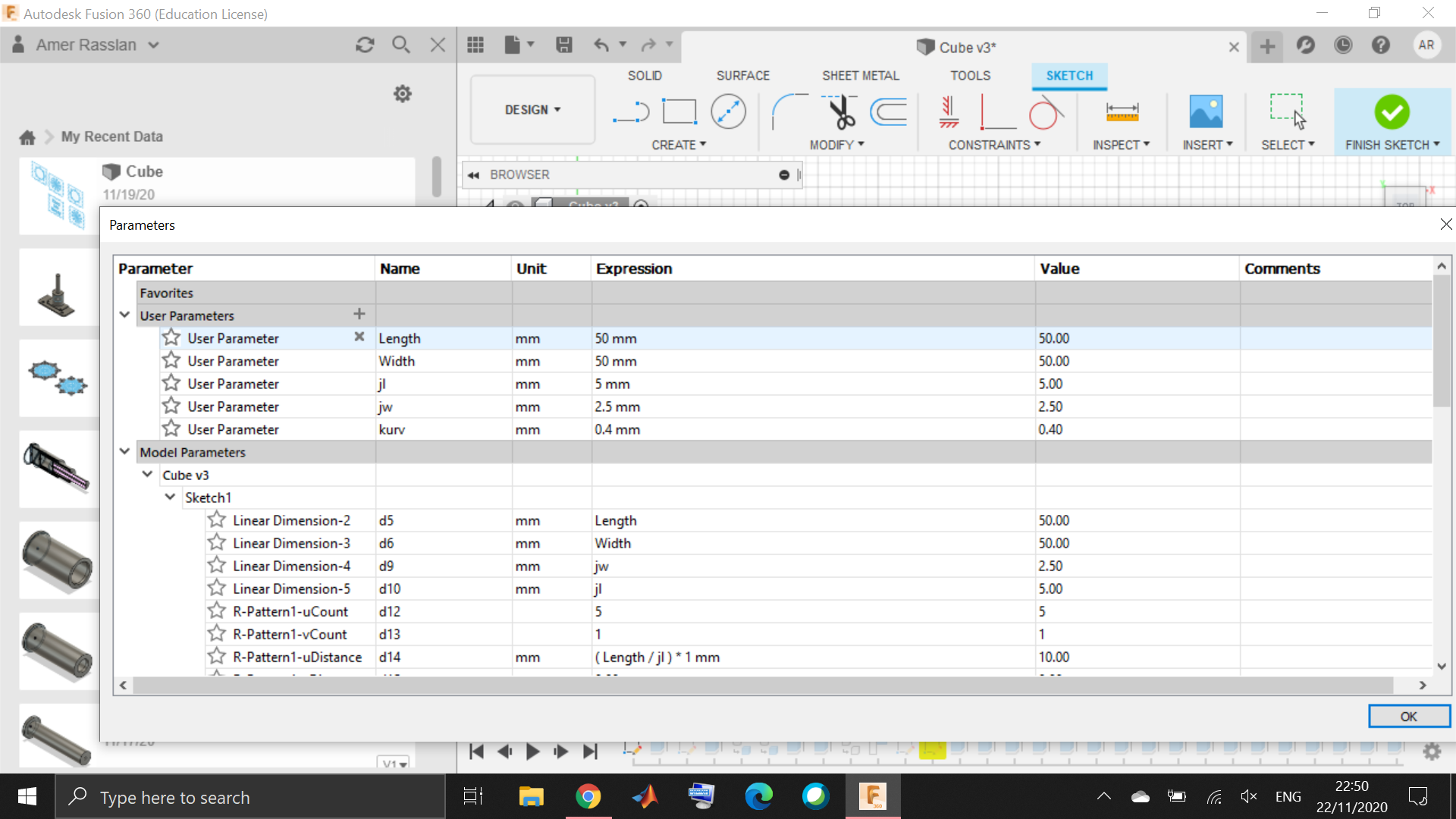

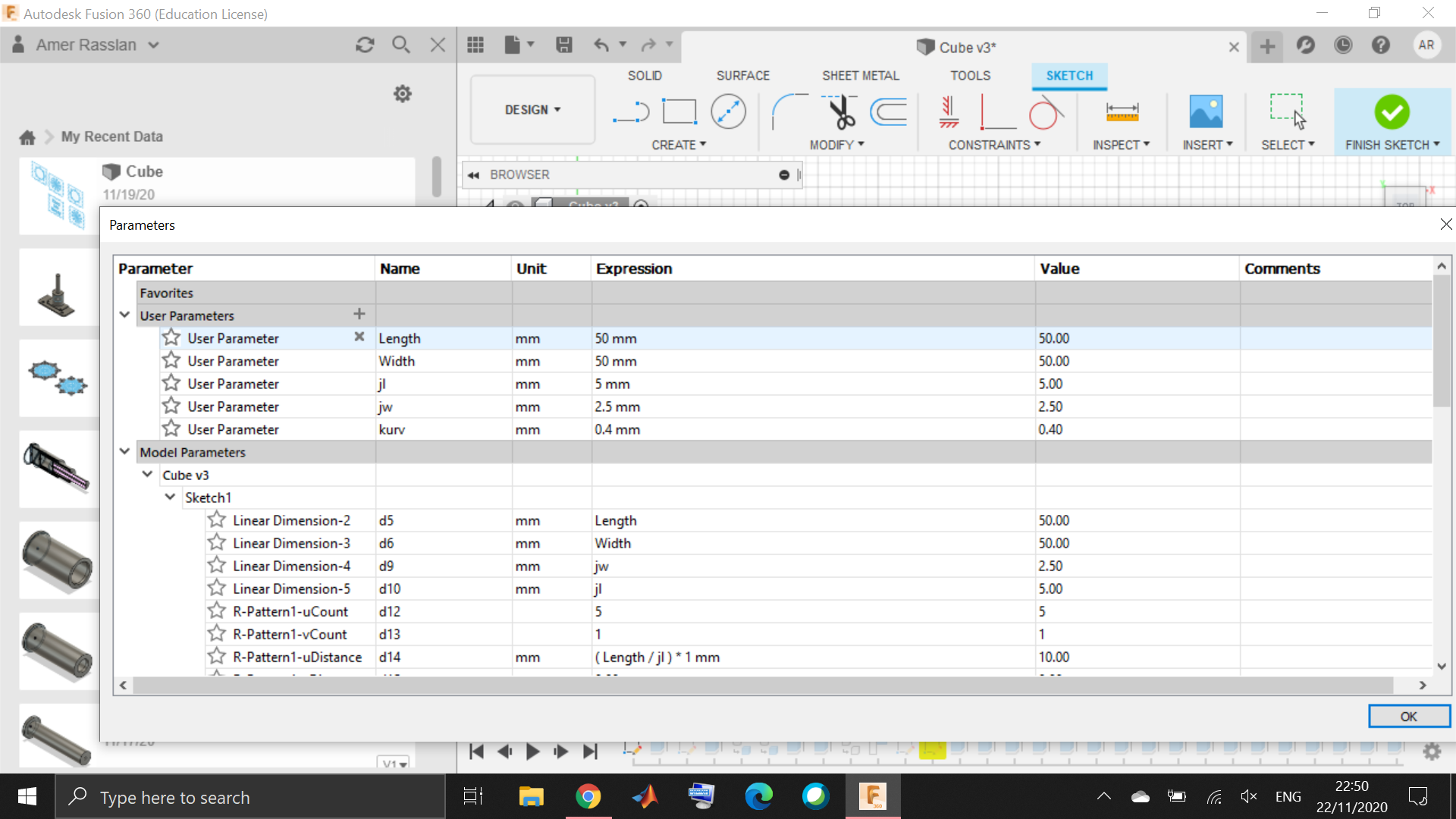

First assigning the parameters of the design as follows

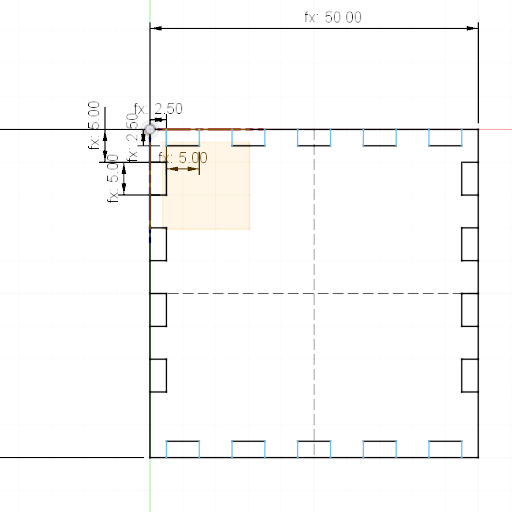

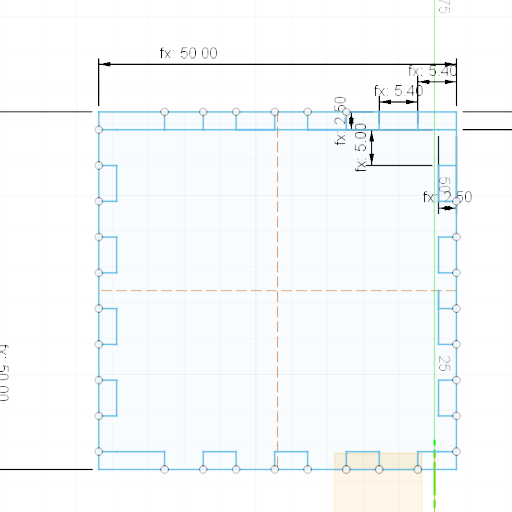

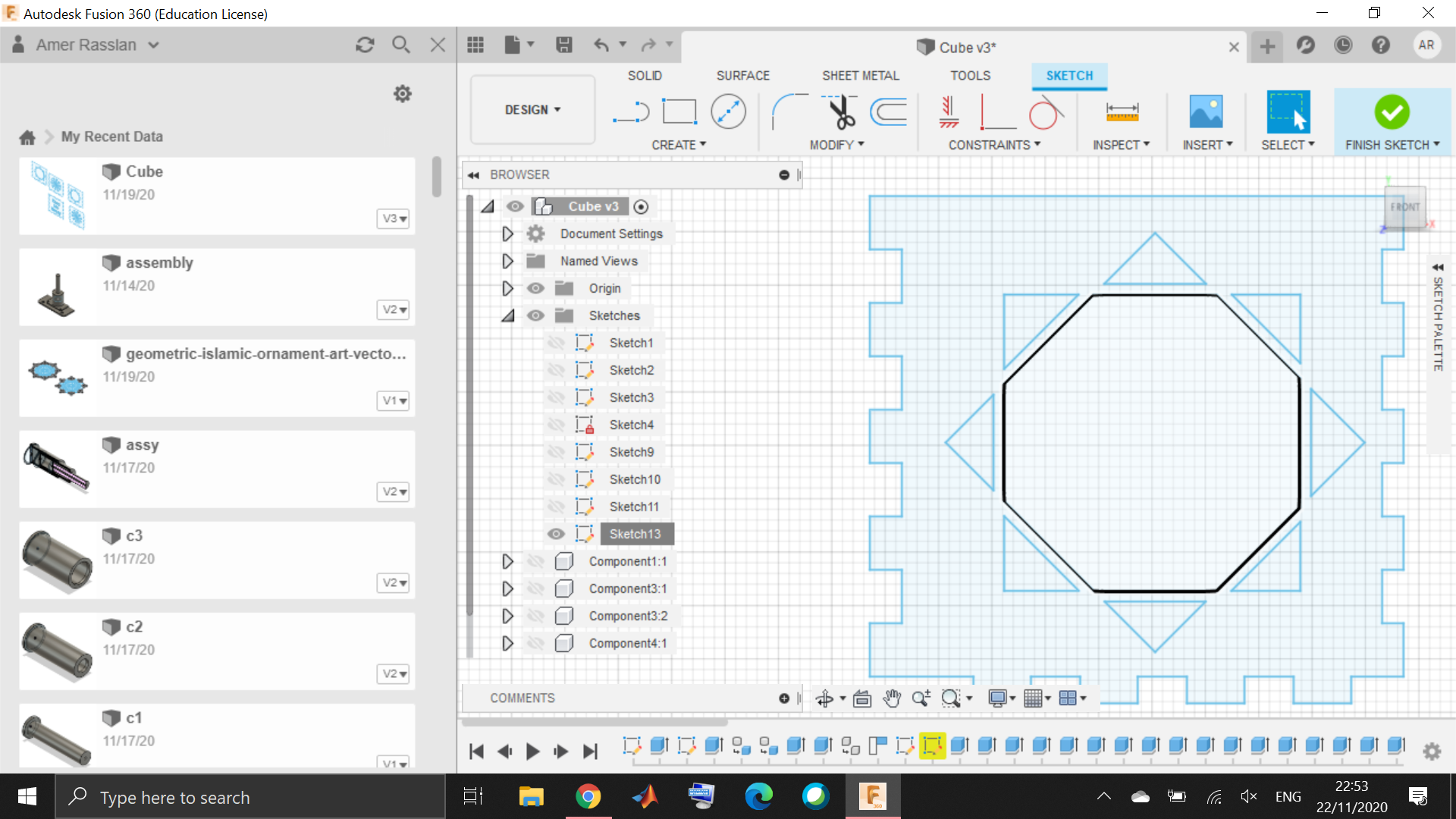

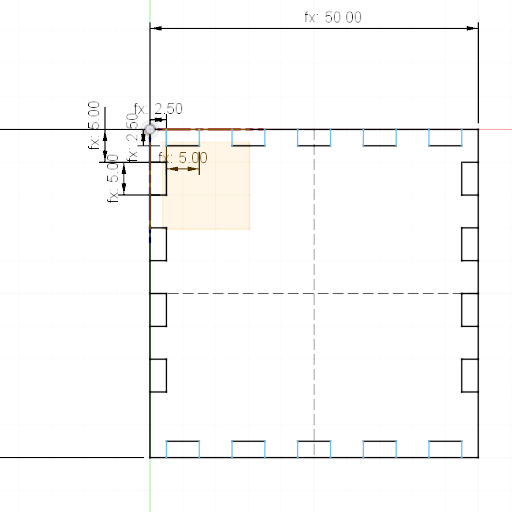

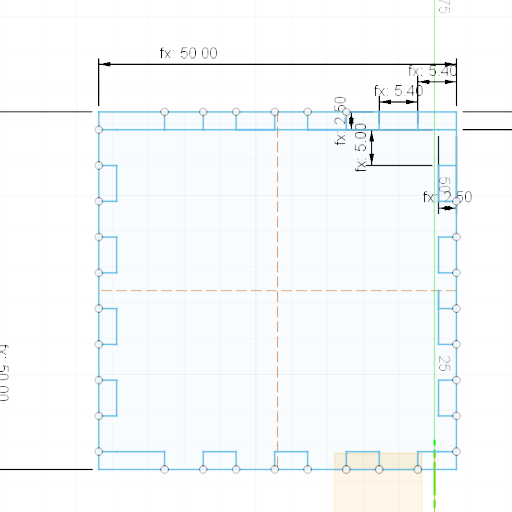

Then starting by the first face using the sketching tool, the face should have these dimentions

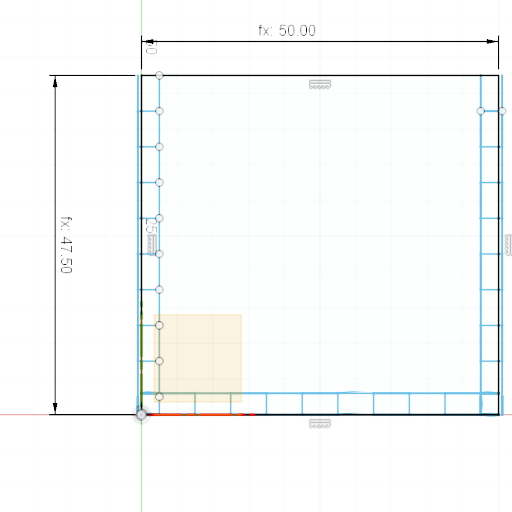

Then sketching the second face using the following dimentions and applying the kurve tolerance of the maschine

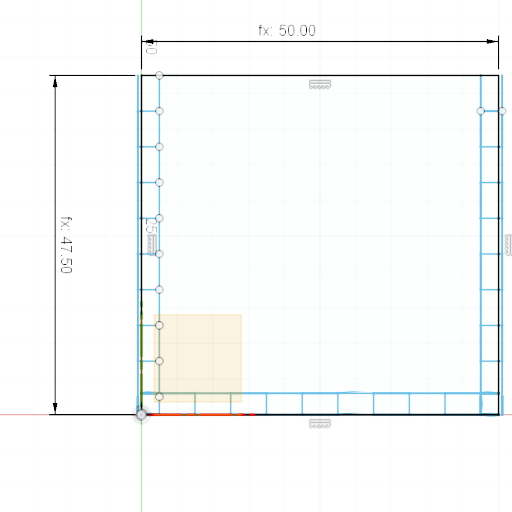

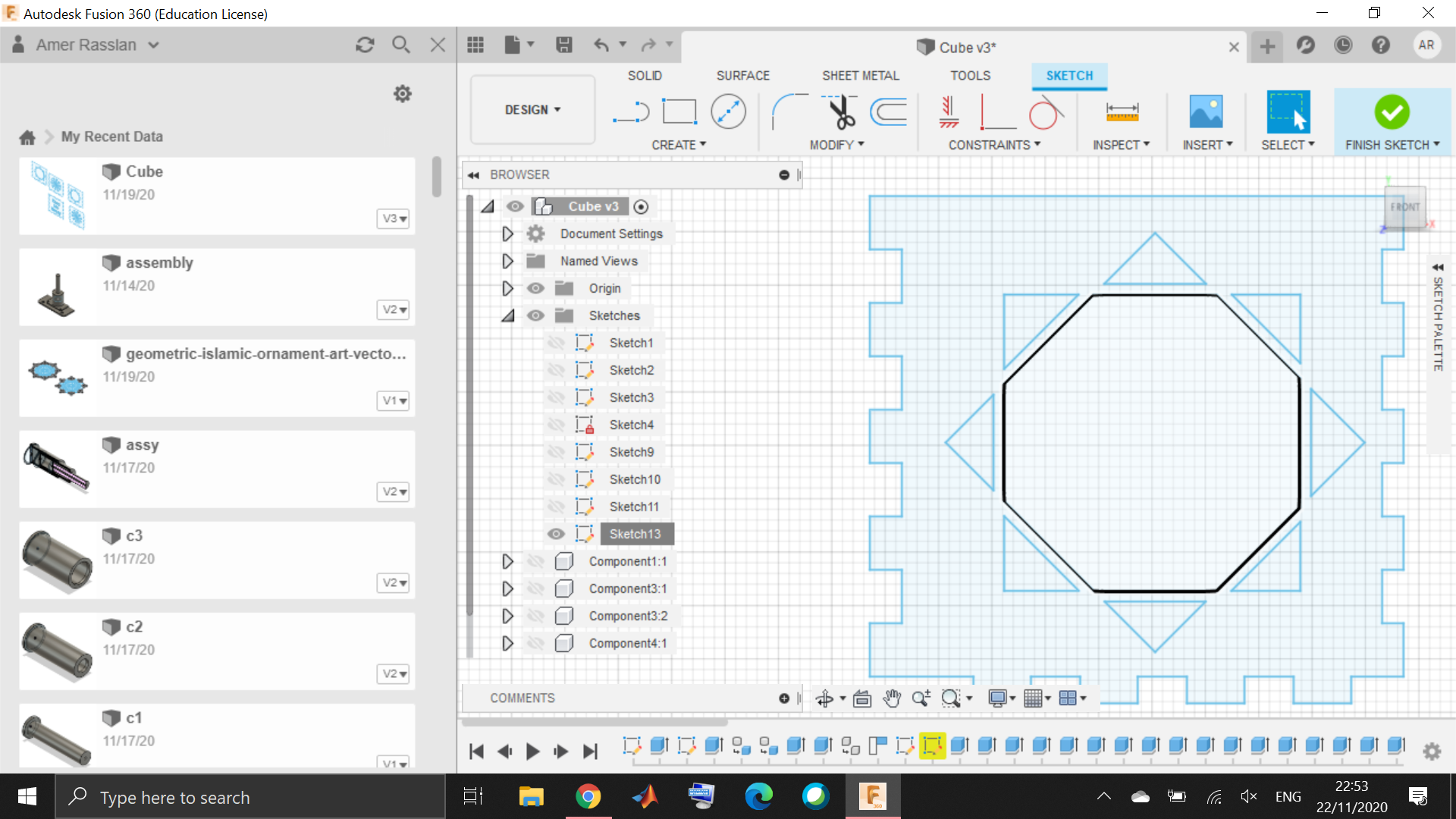

As the cube is assymetric only one face is left to sketch which can be done as follows

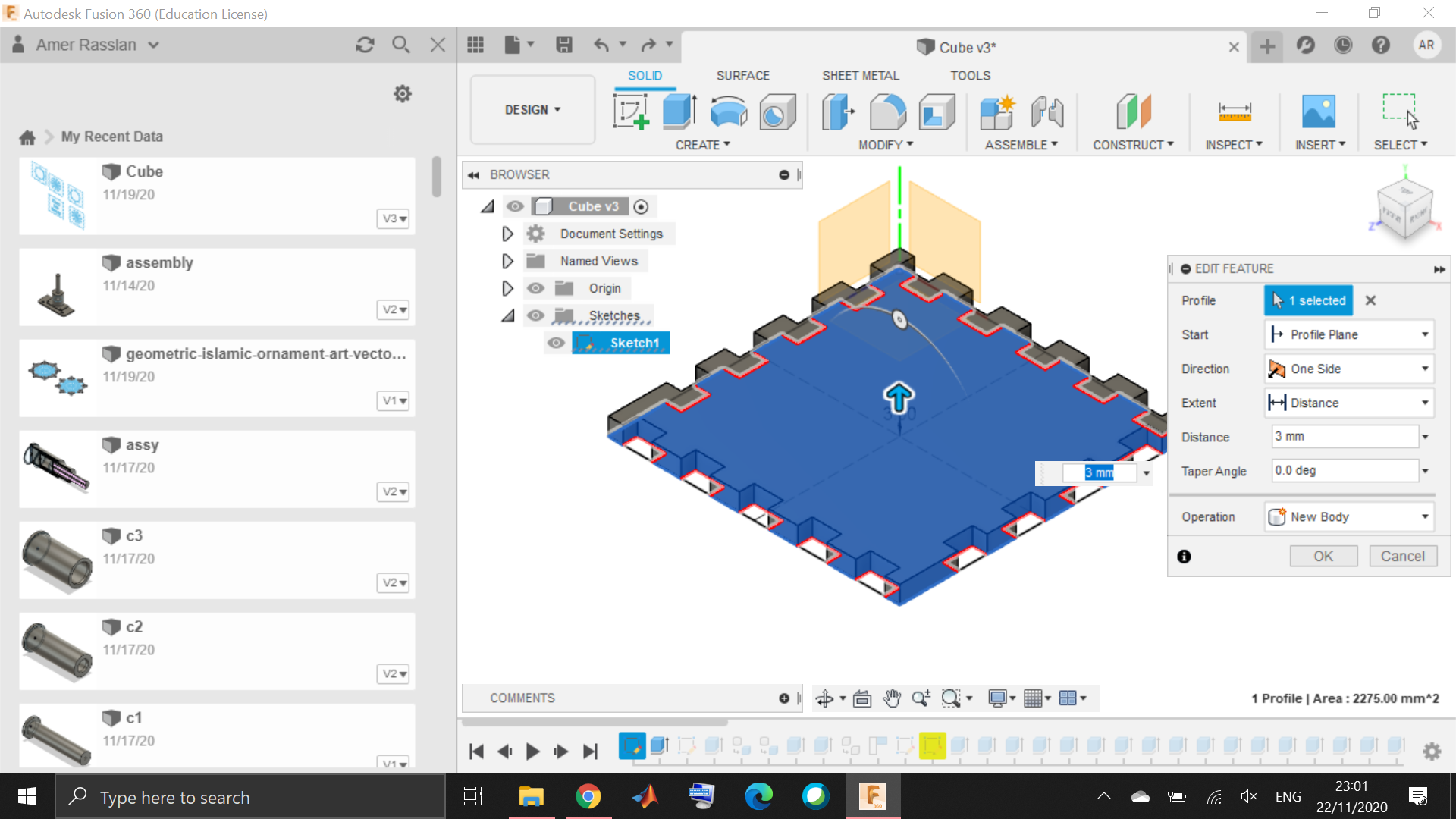

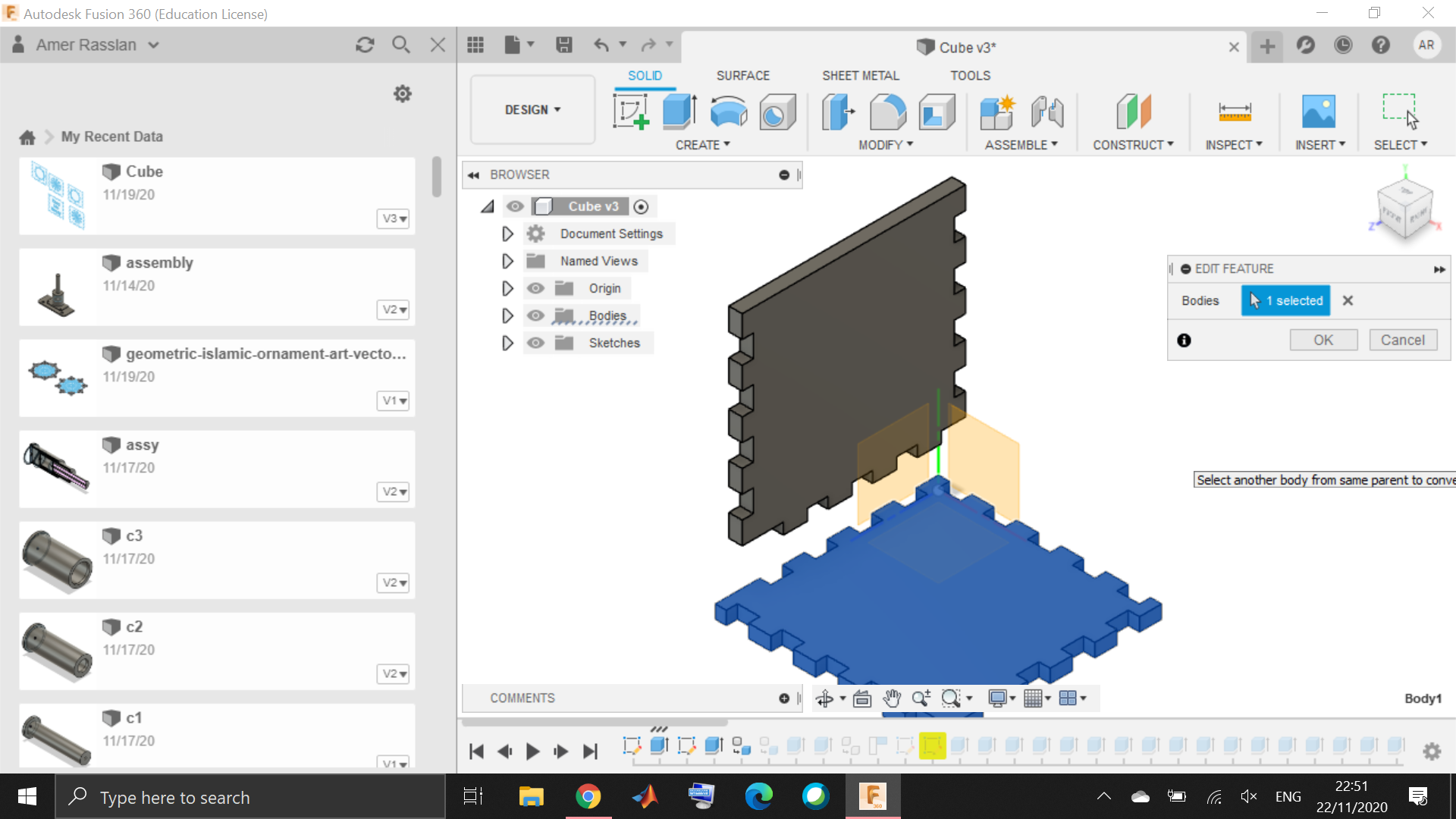

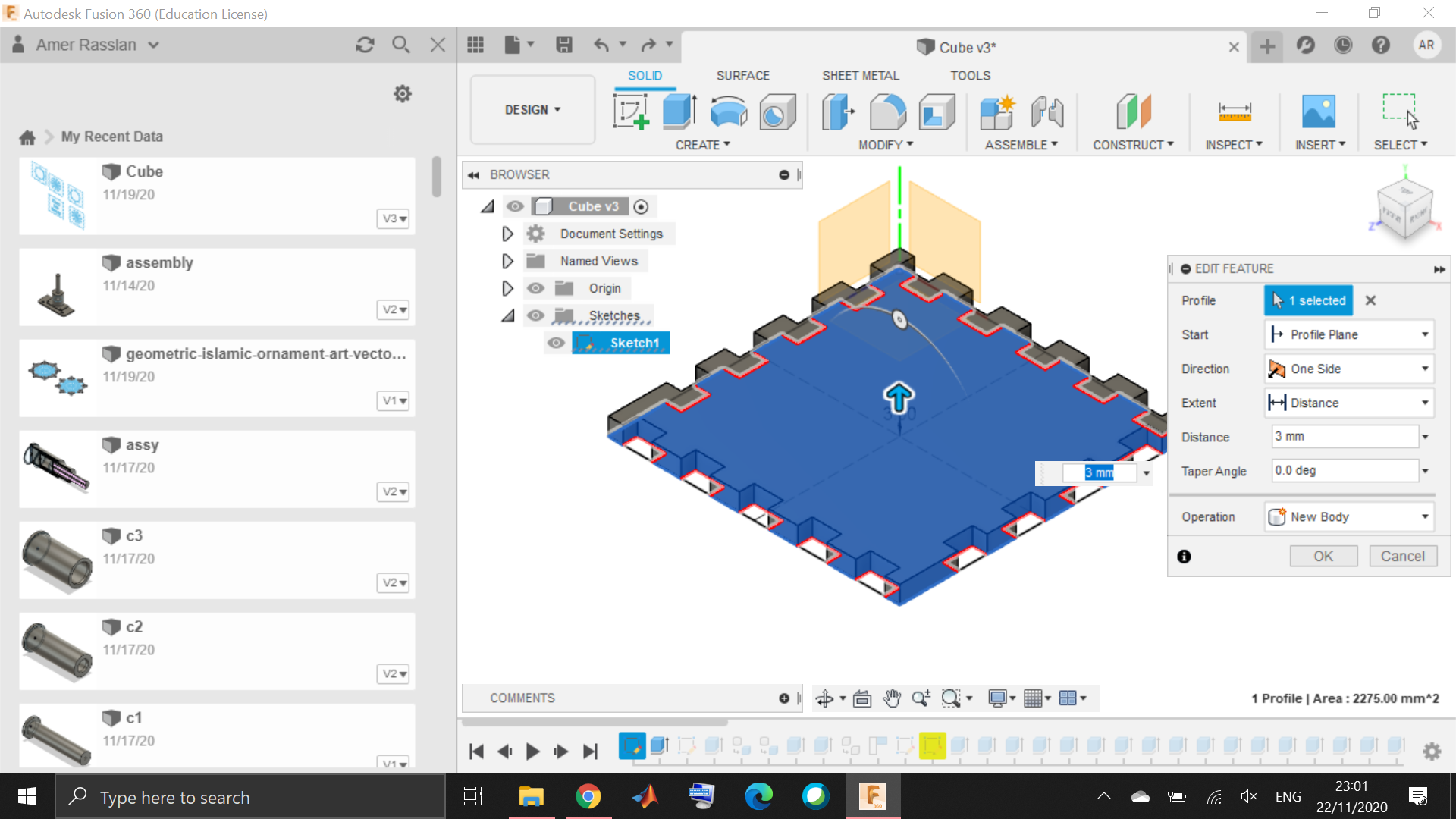

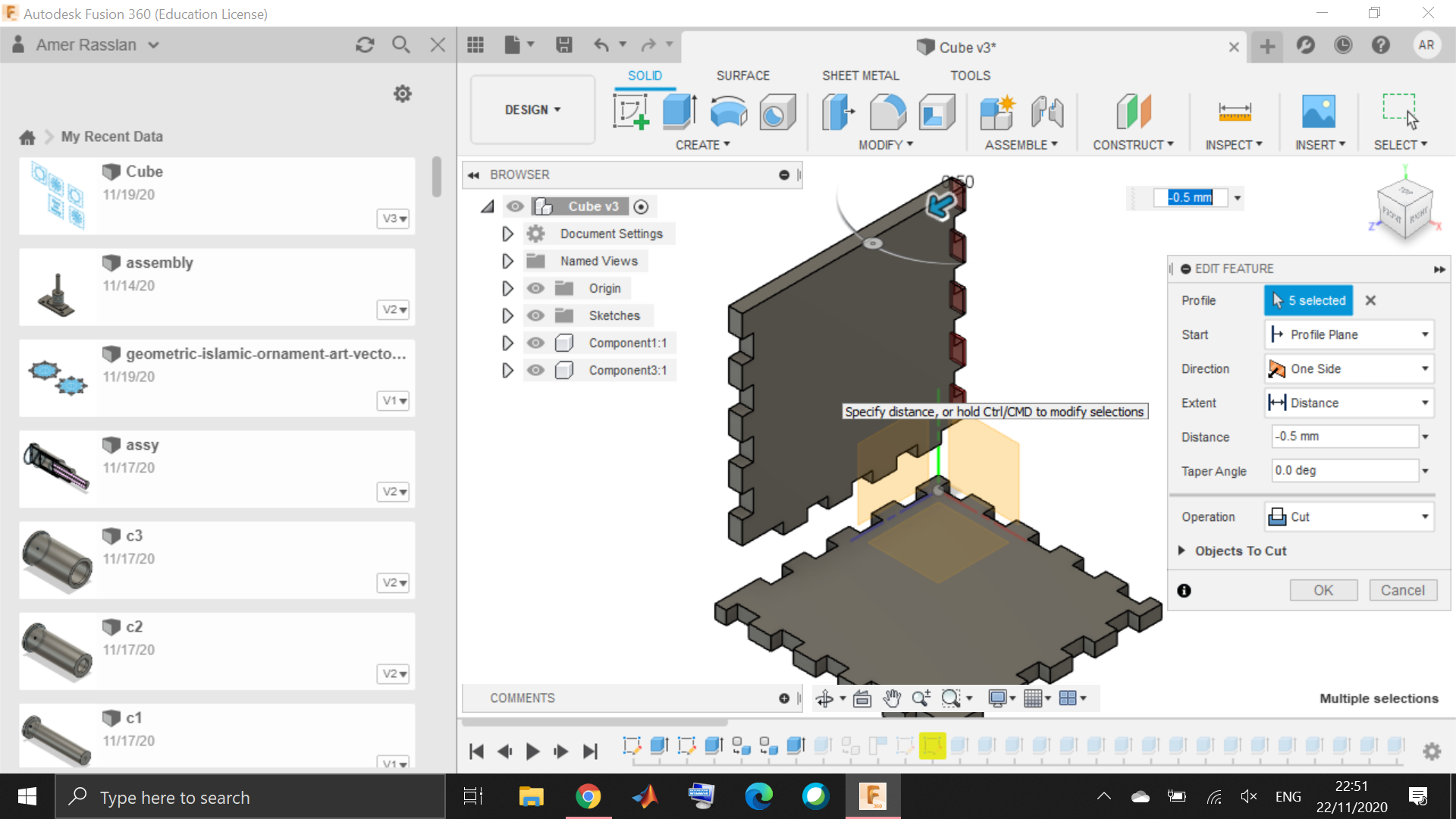

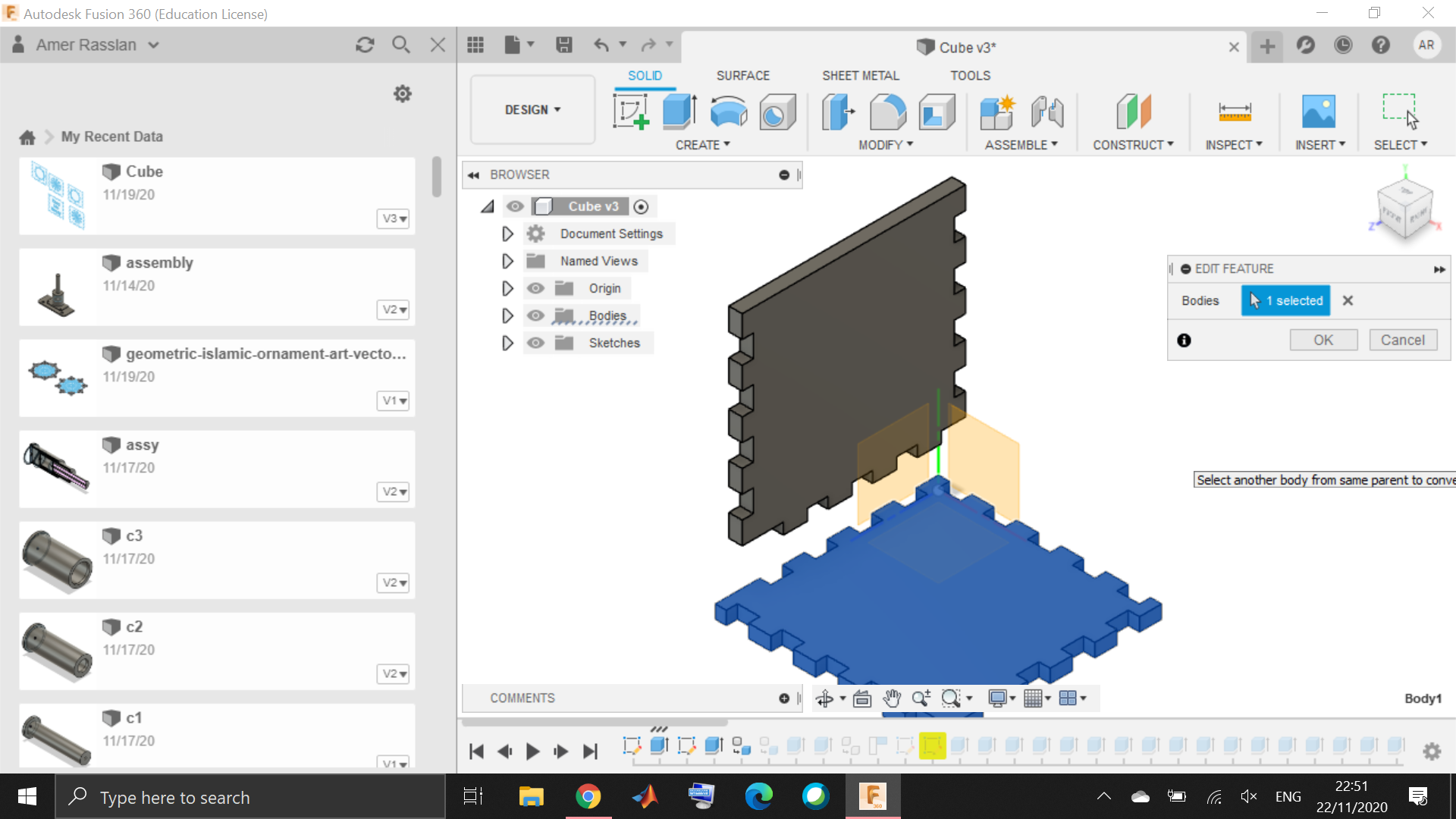

Then extruding the three faces and copying face 1,2 with 3 mm material thickness

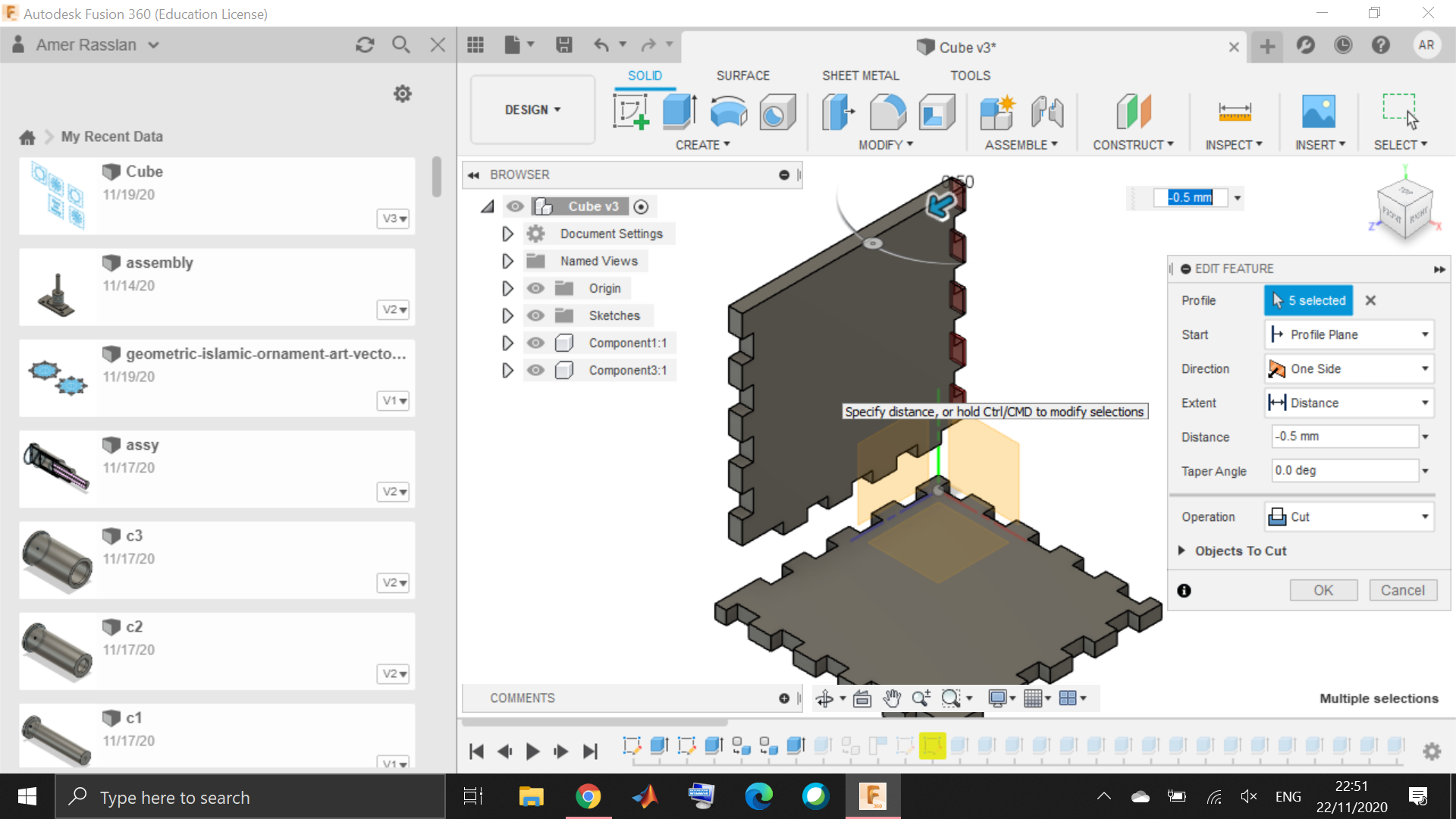

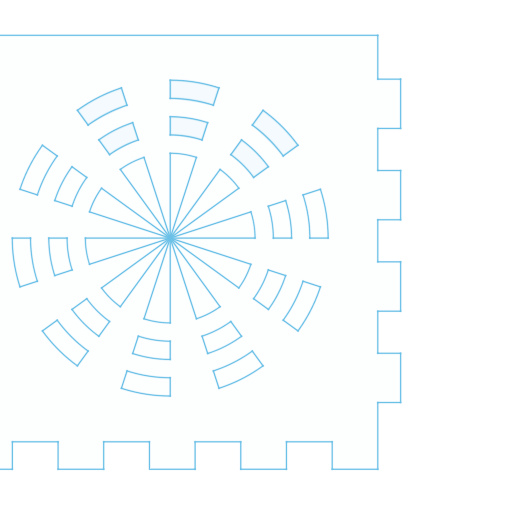

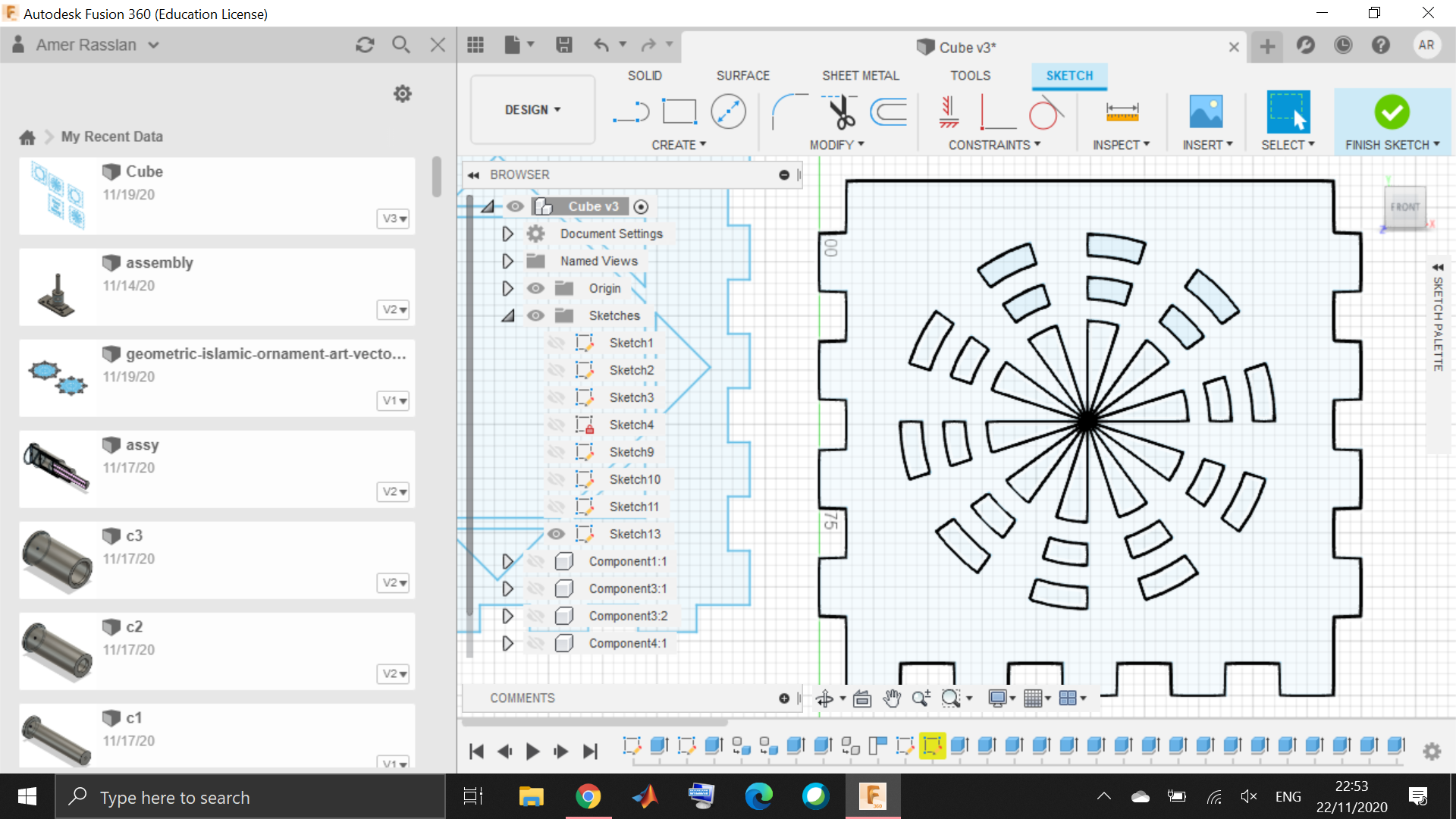

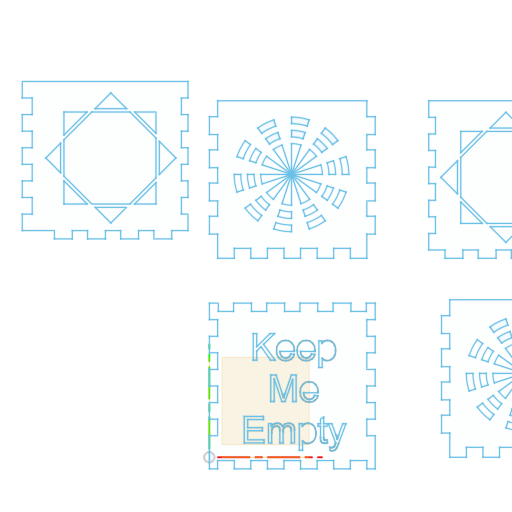

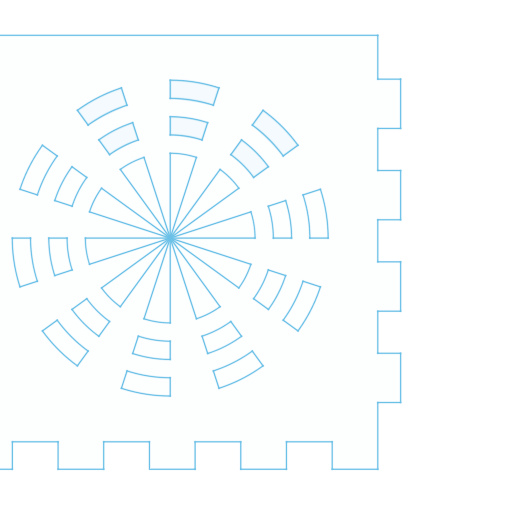

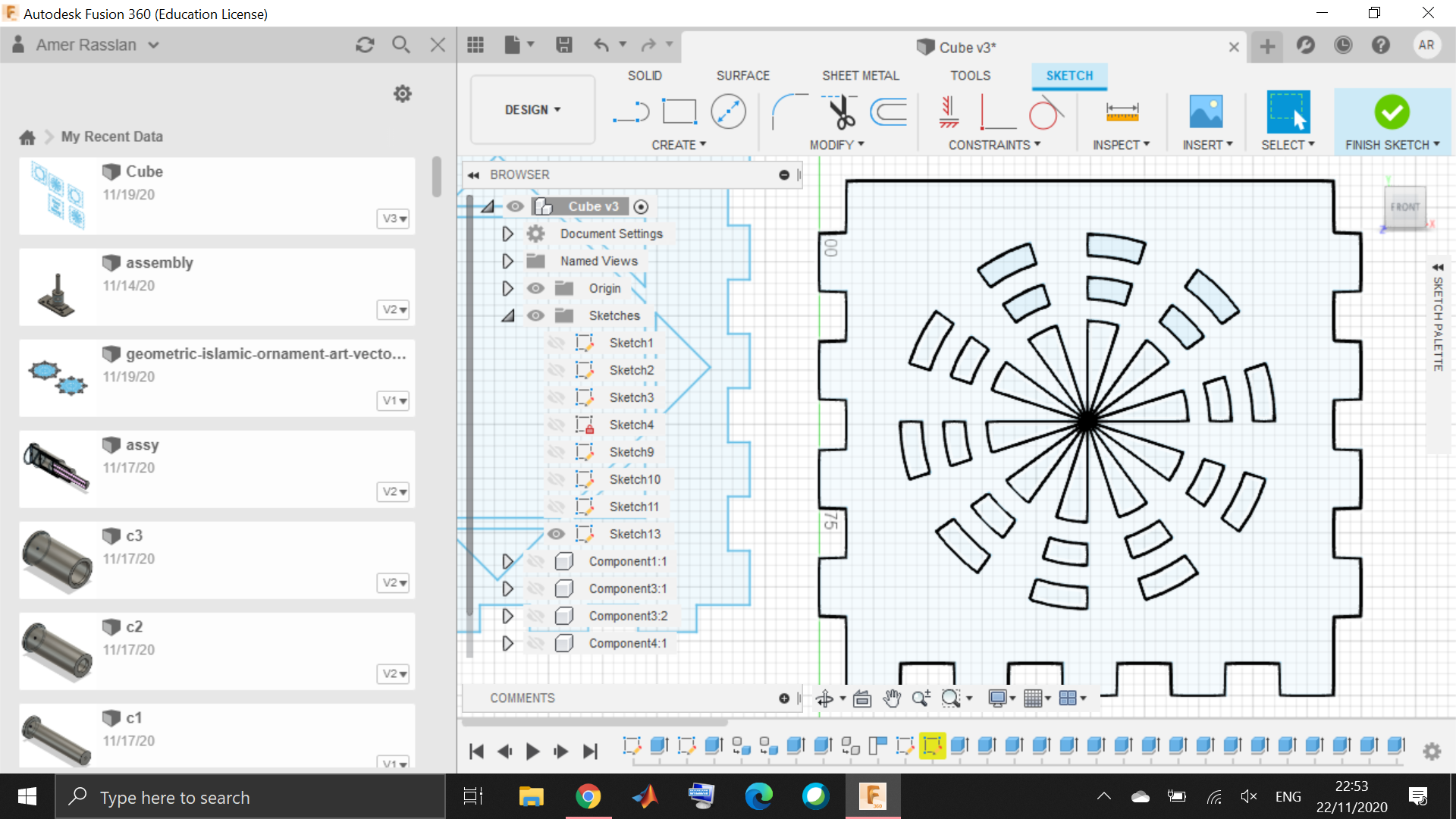

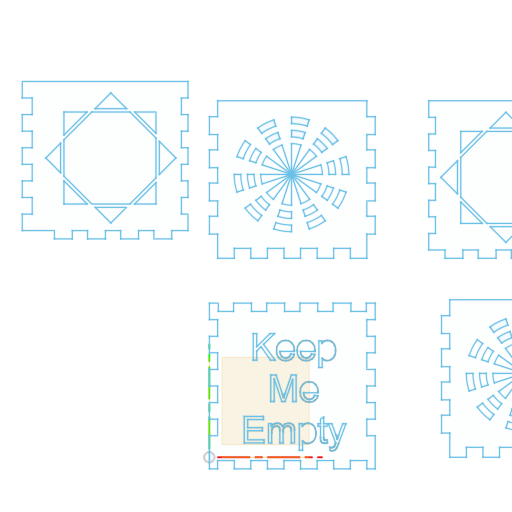

Now the detailing of the faces consists of a fully cut patterns on the side faces and an engraving on the bottom face, These can be achived using the folowing sketch

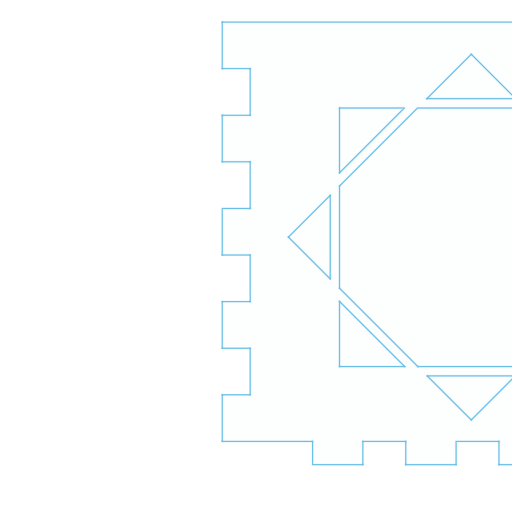

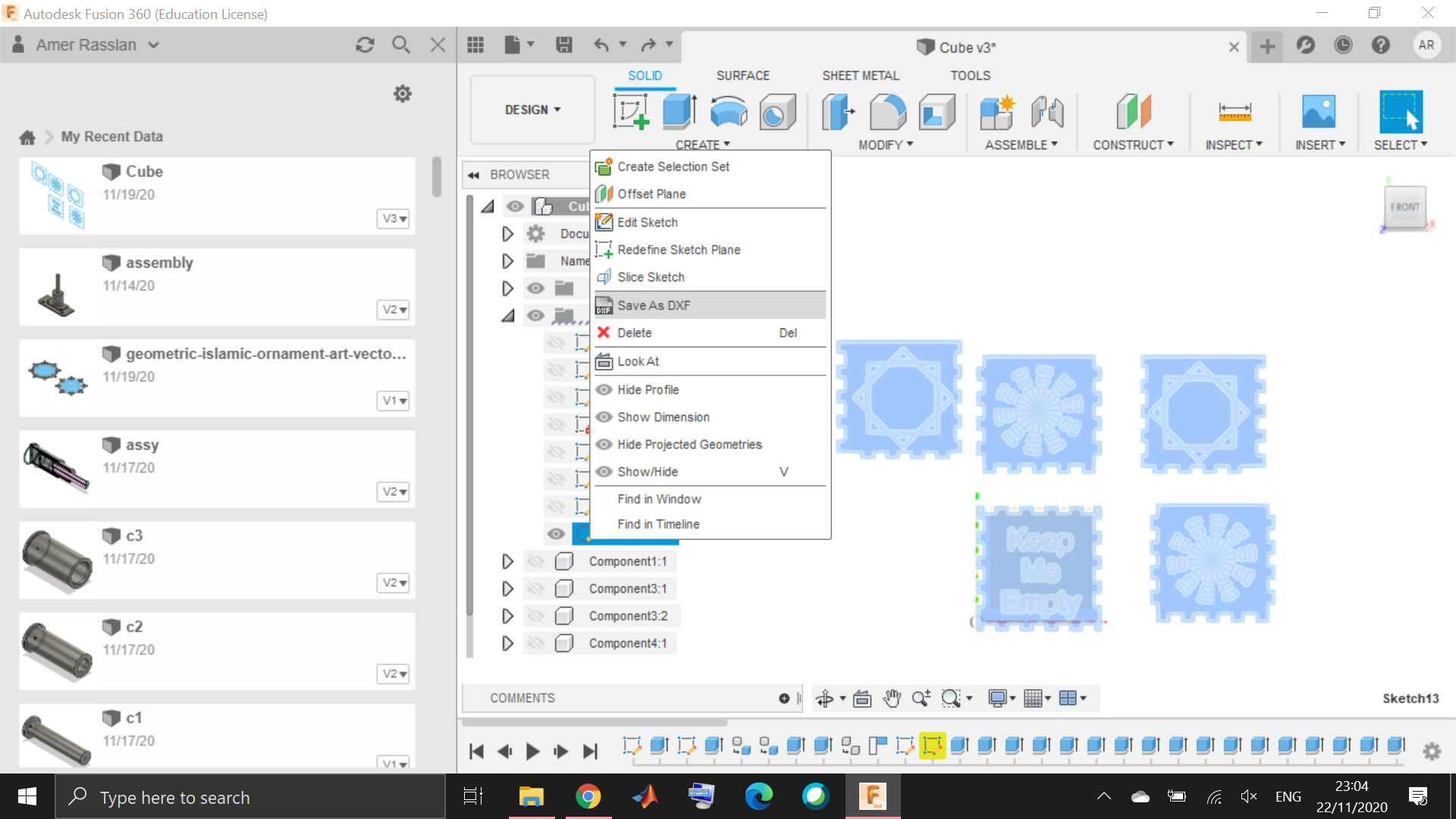

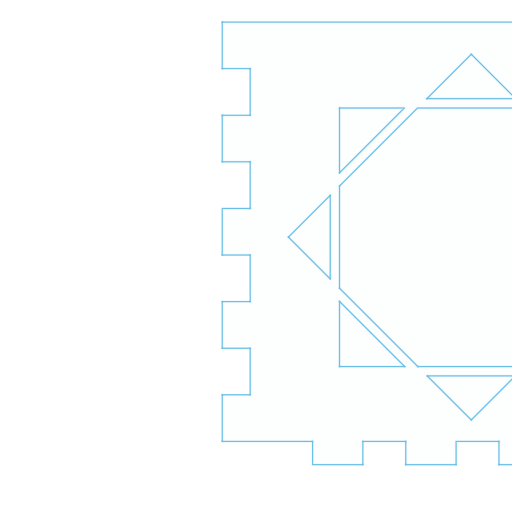

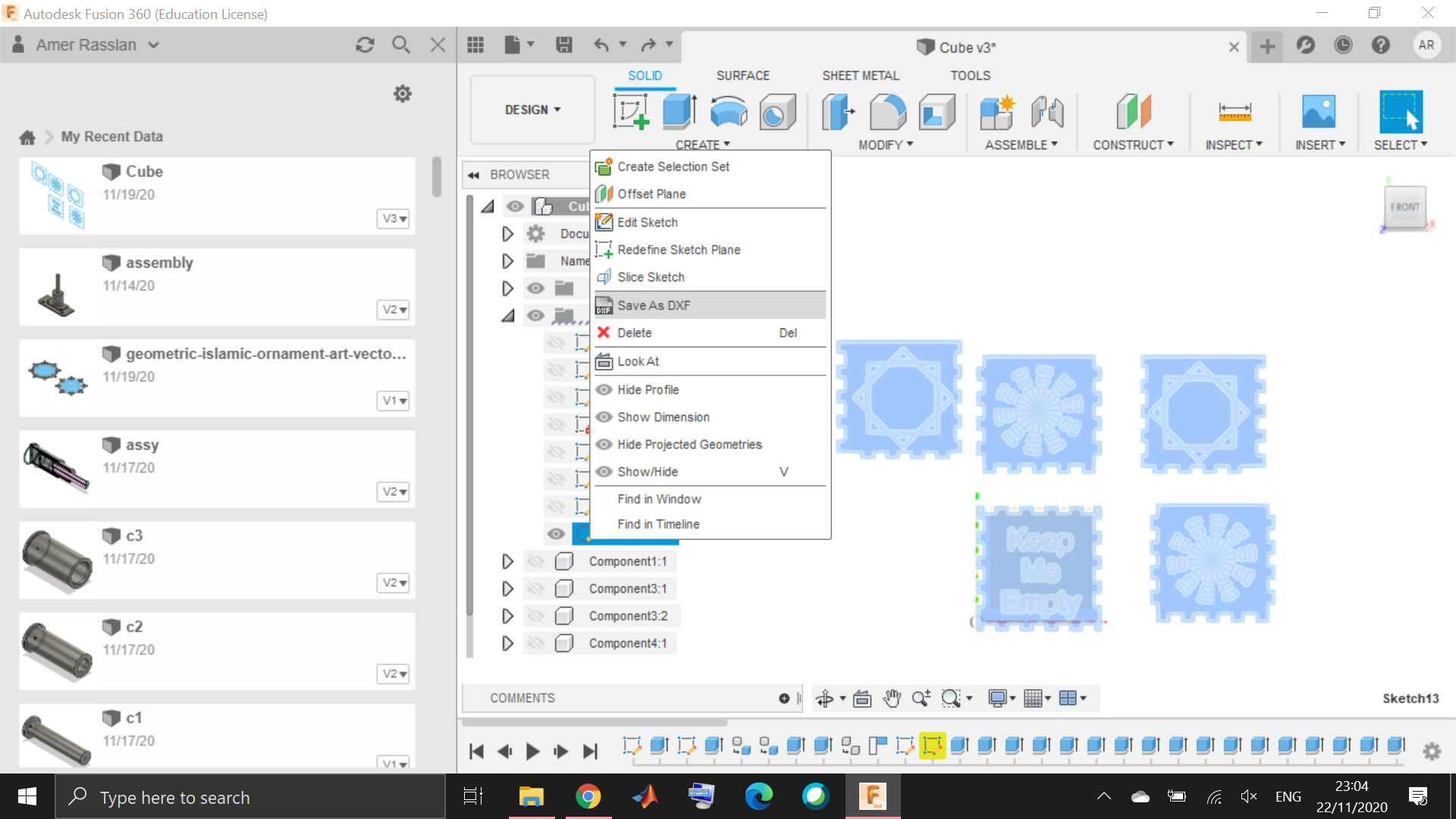

in order to extract the file fed into the laser cutting maschine, the faces are projected using the project tool then selecting the faces and saving the sketch as dxf file

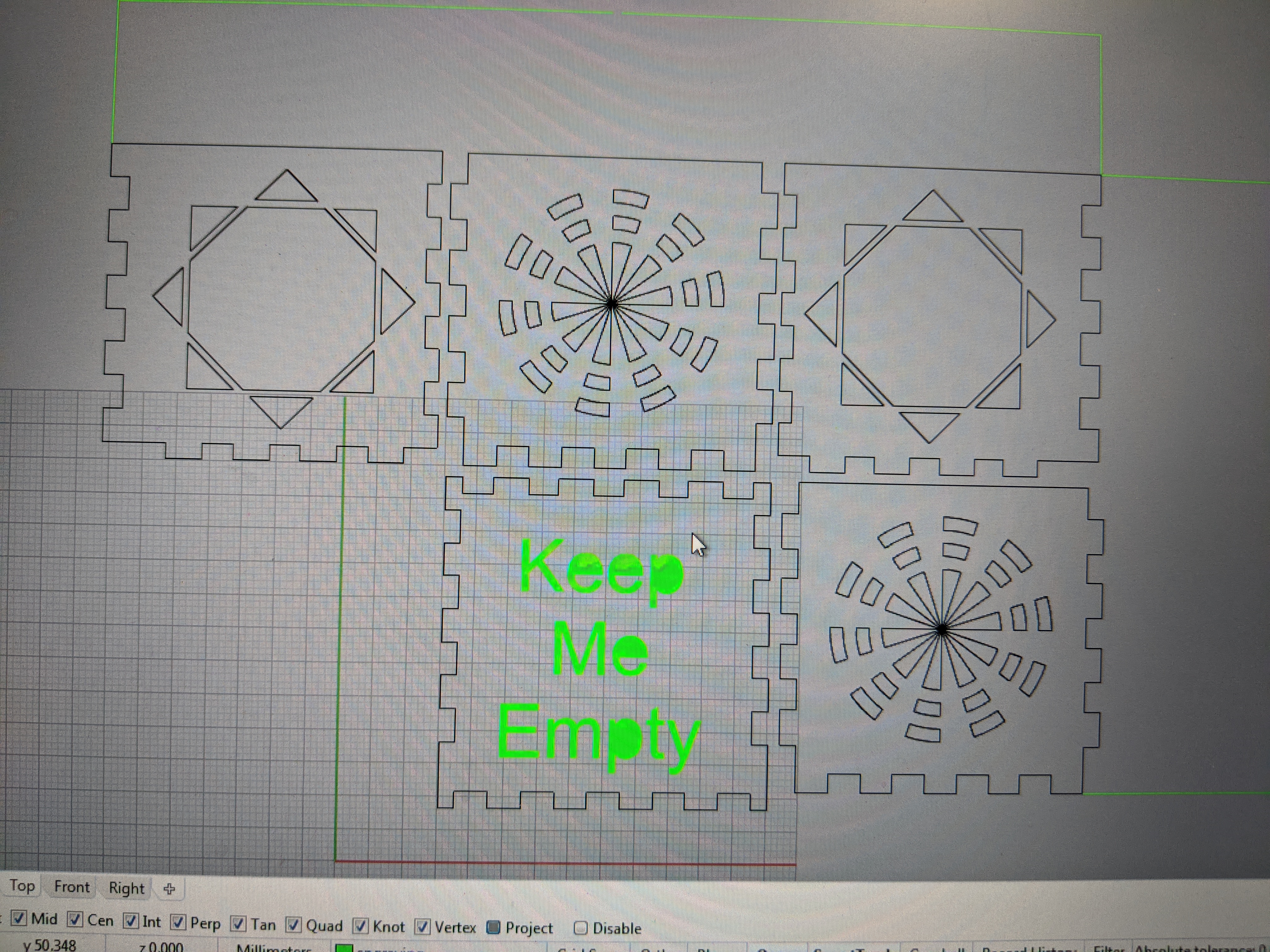

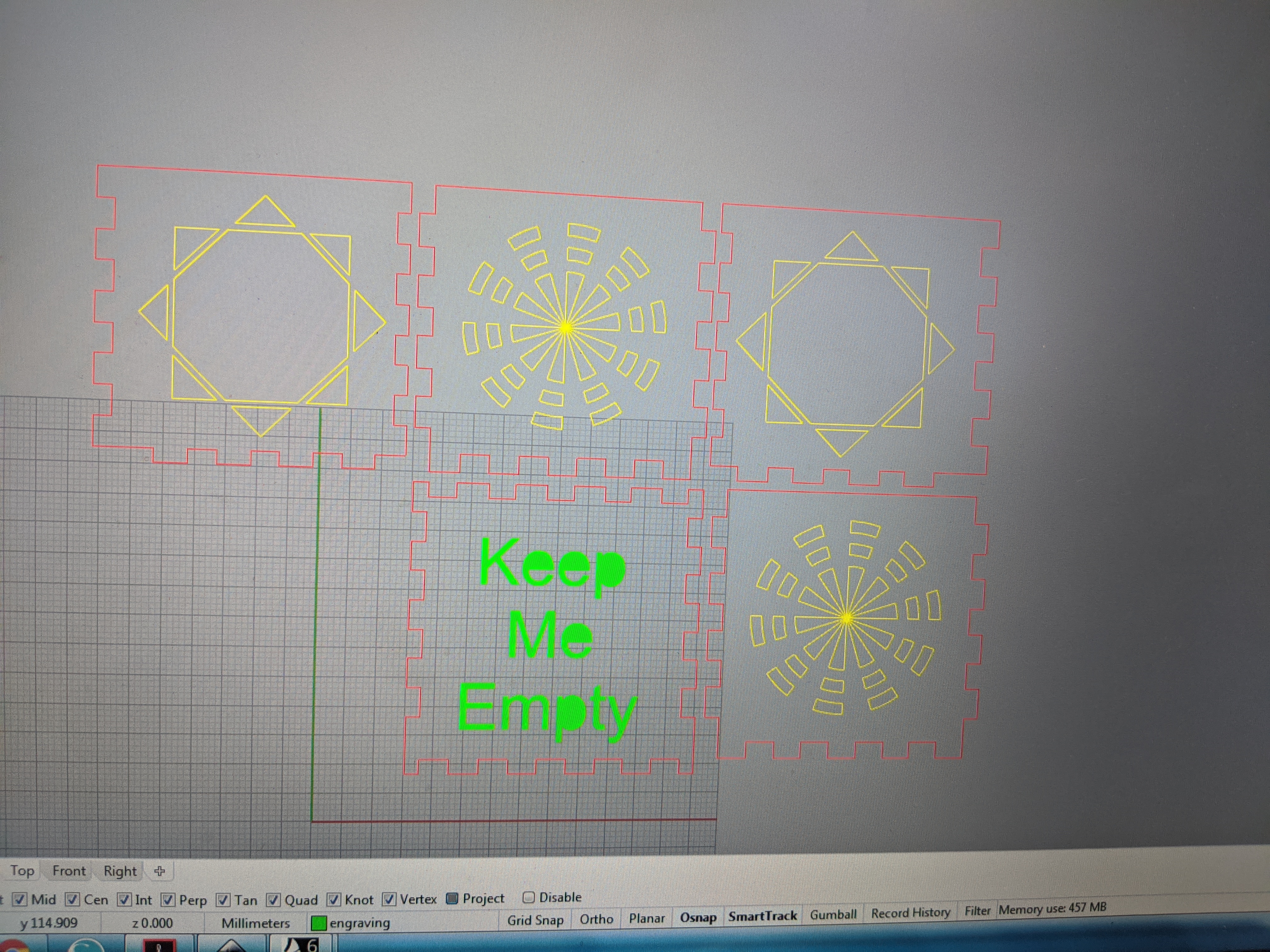

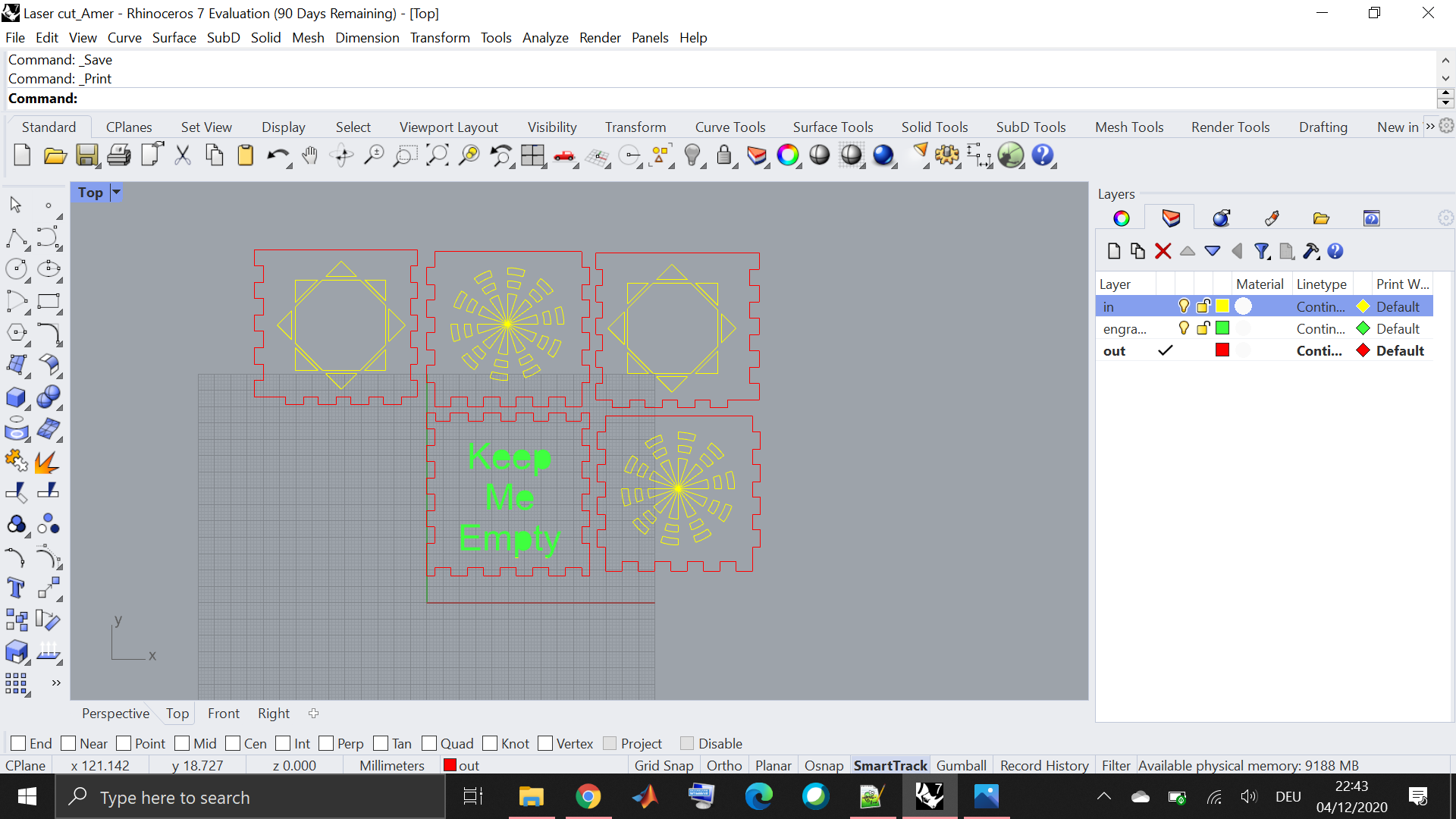

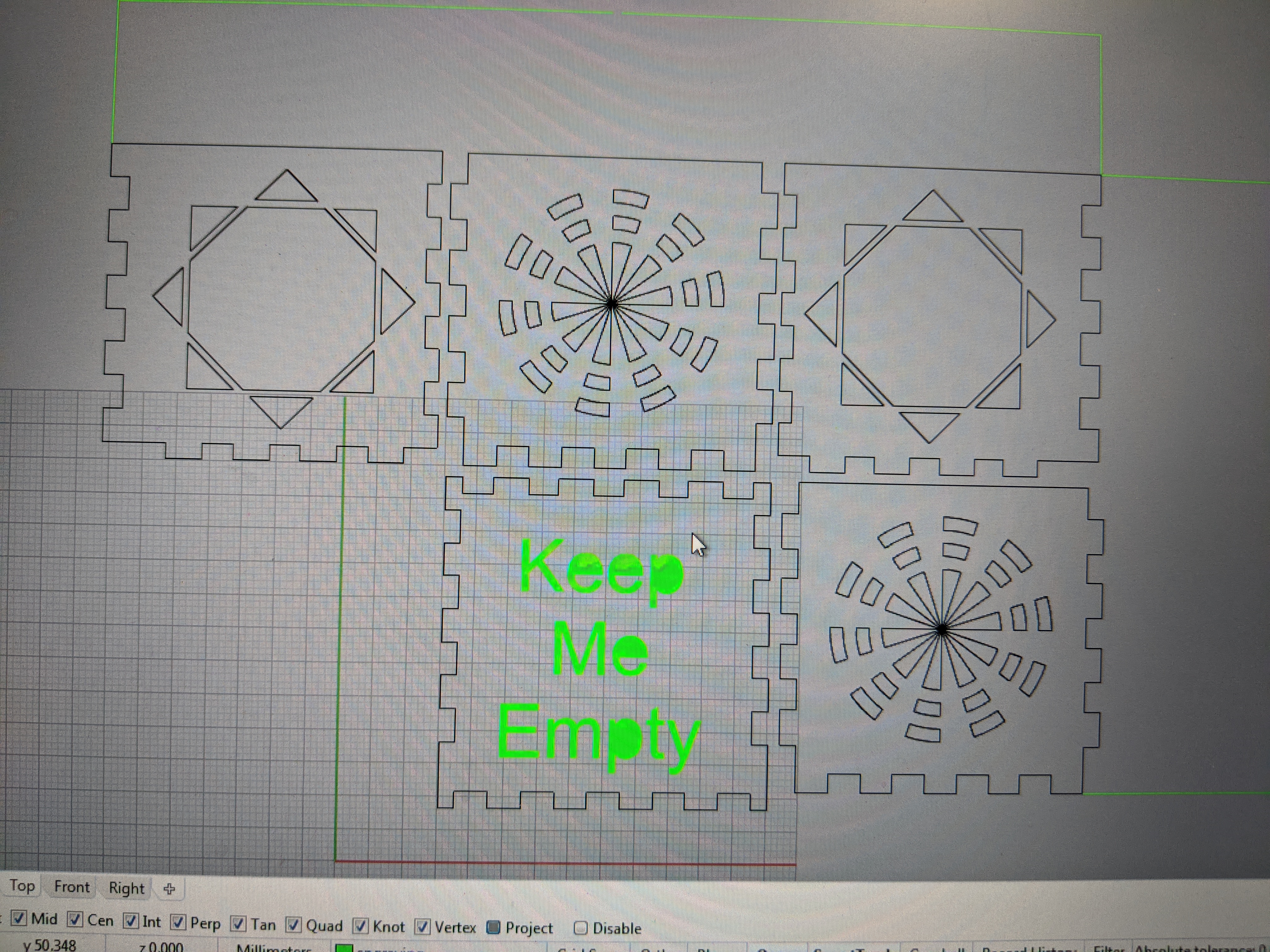

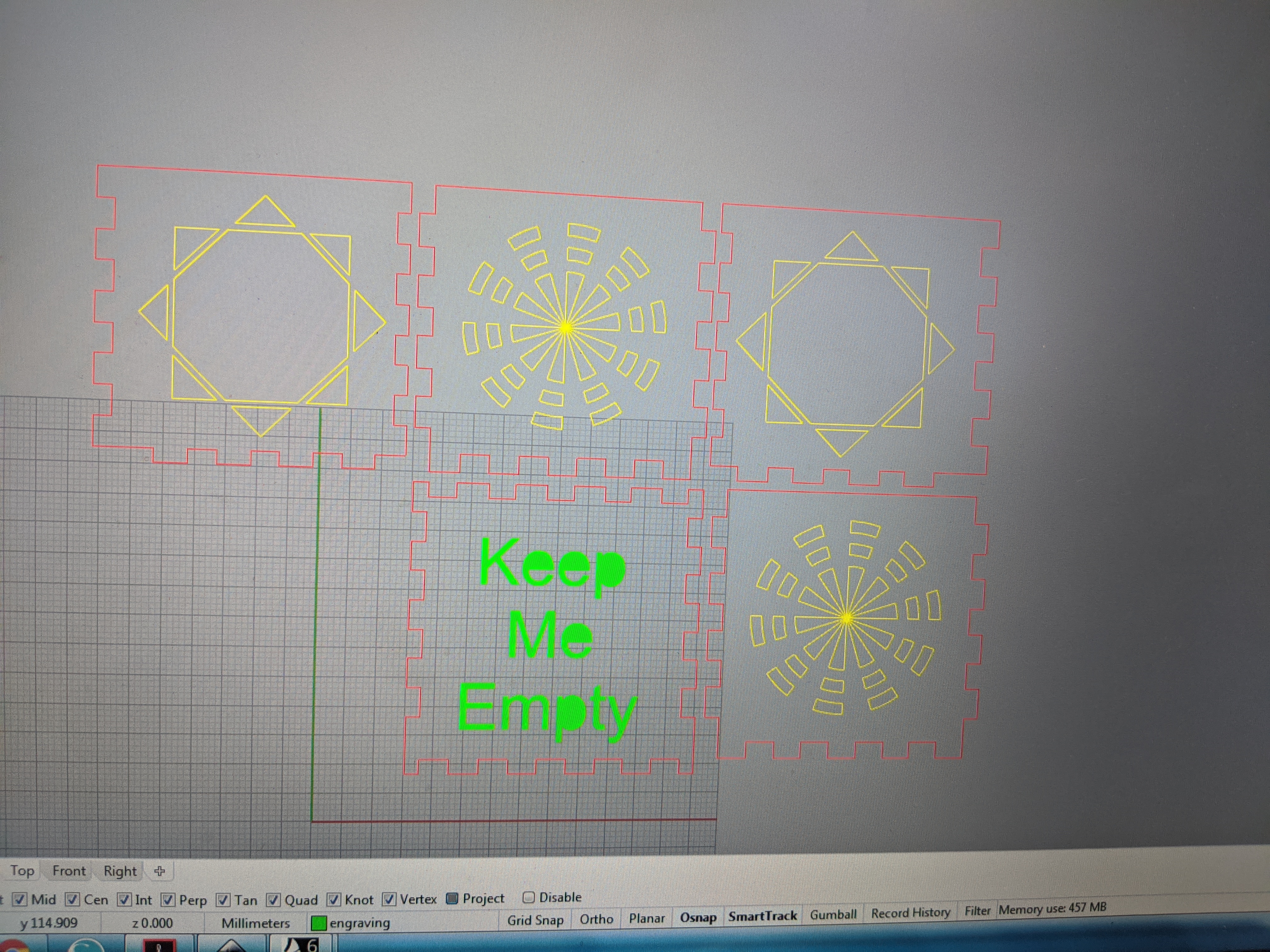

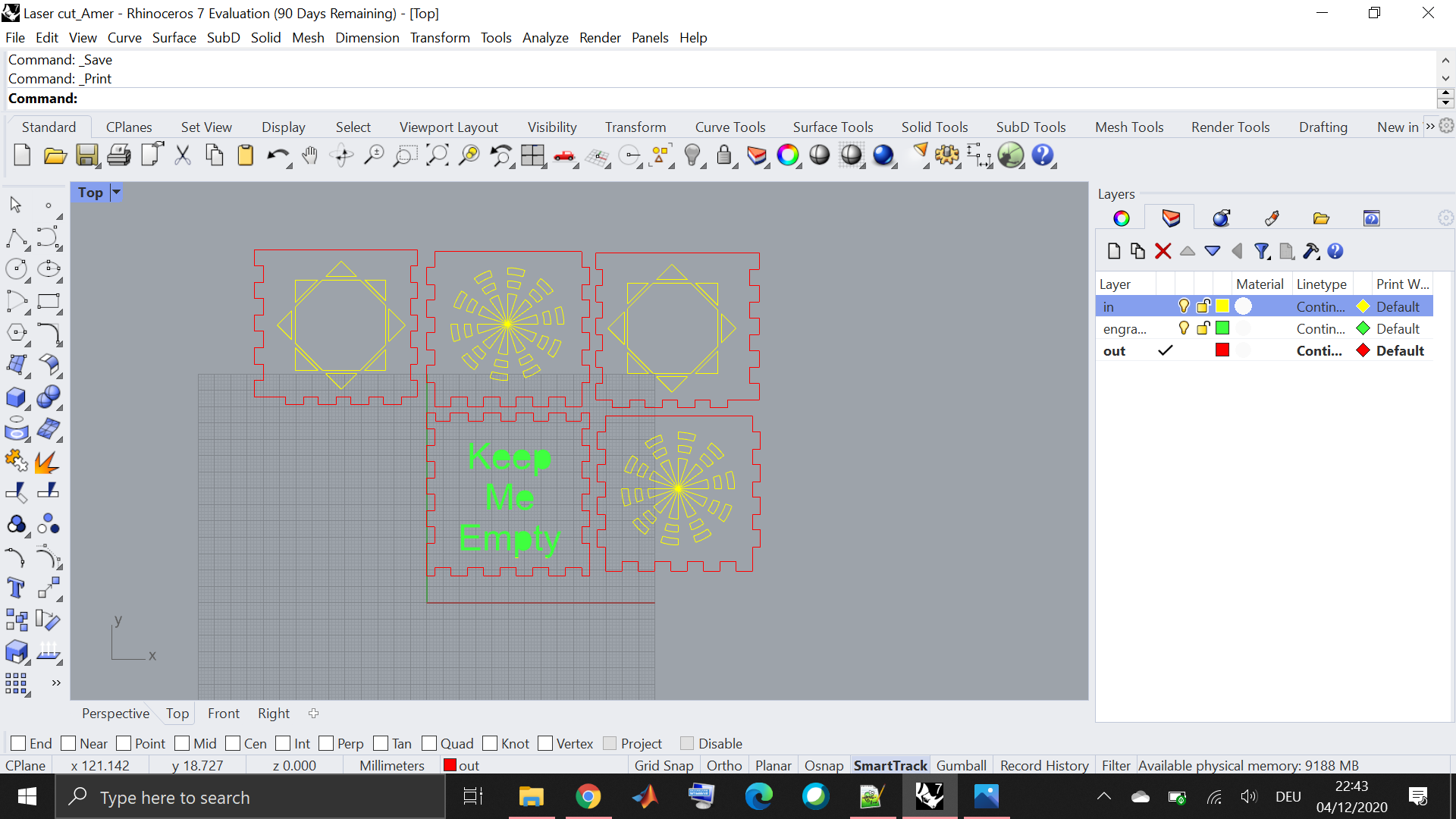

Now the dxf file is transefered to the laser cutting program connected to the machine which is Rhinos, The design is alligned in a new file as follows

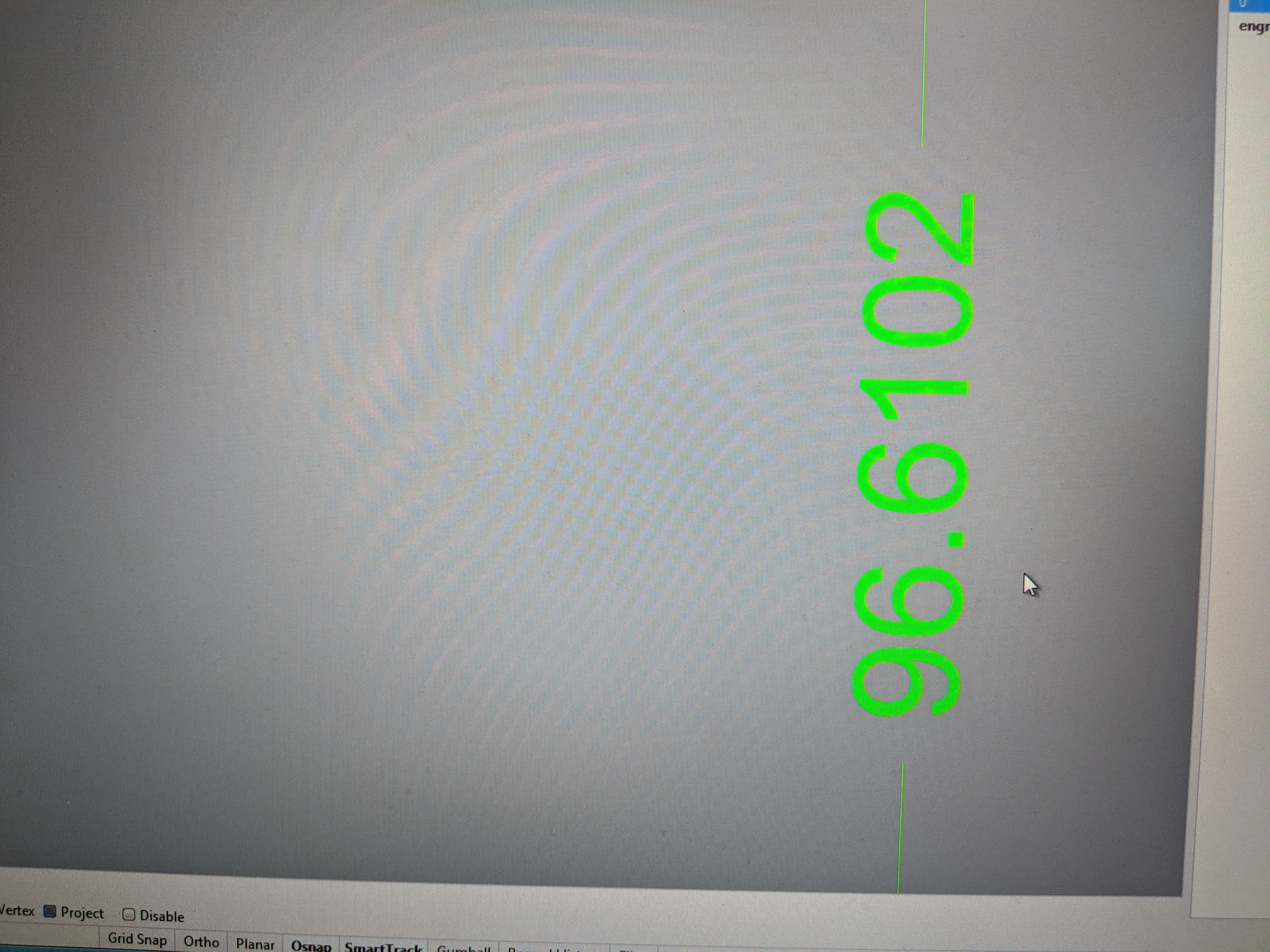

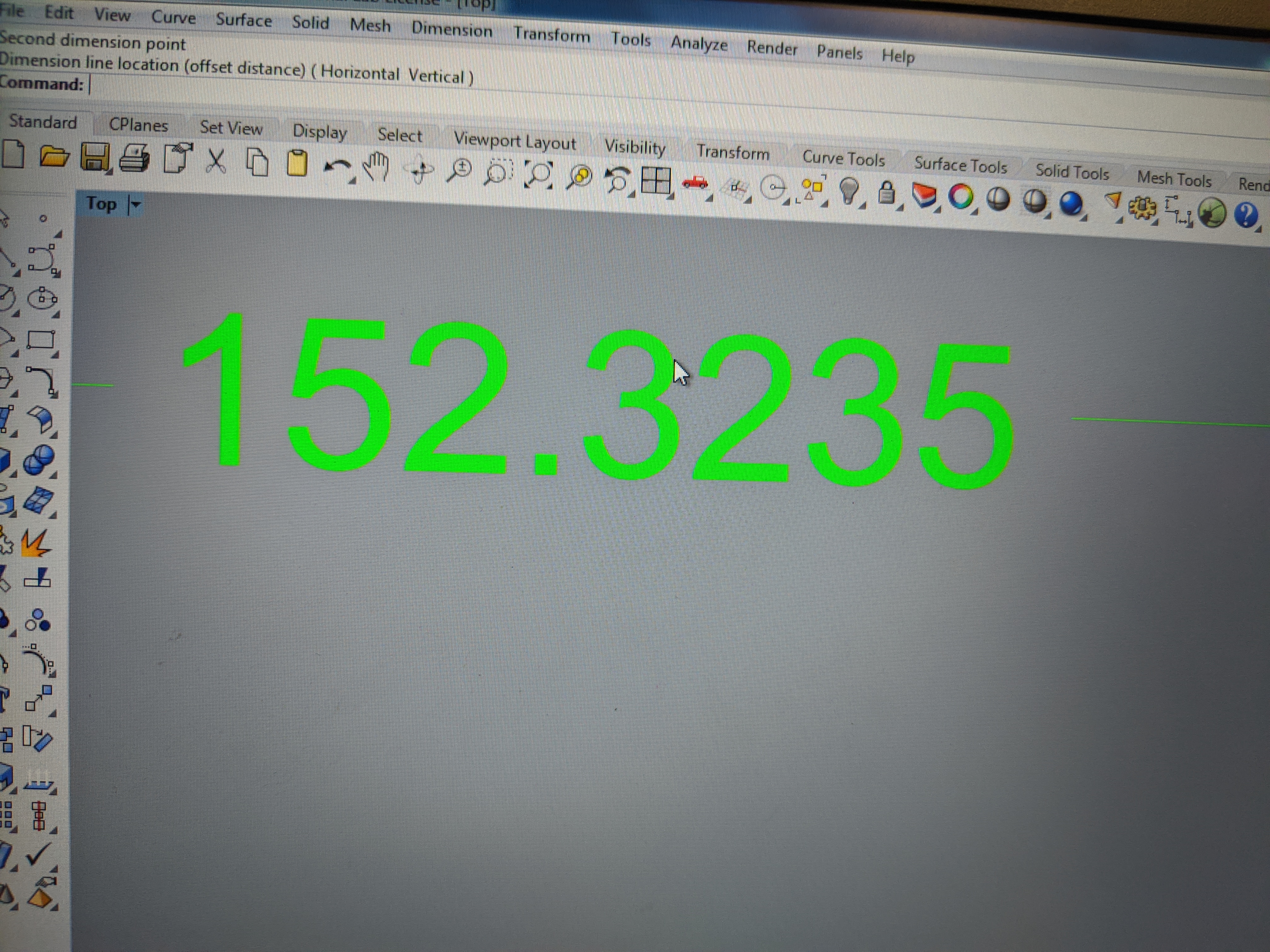

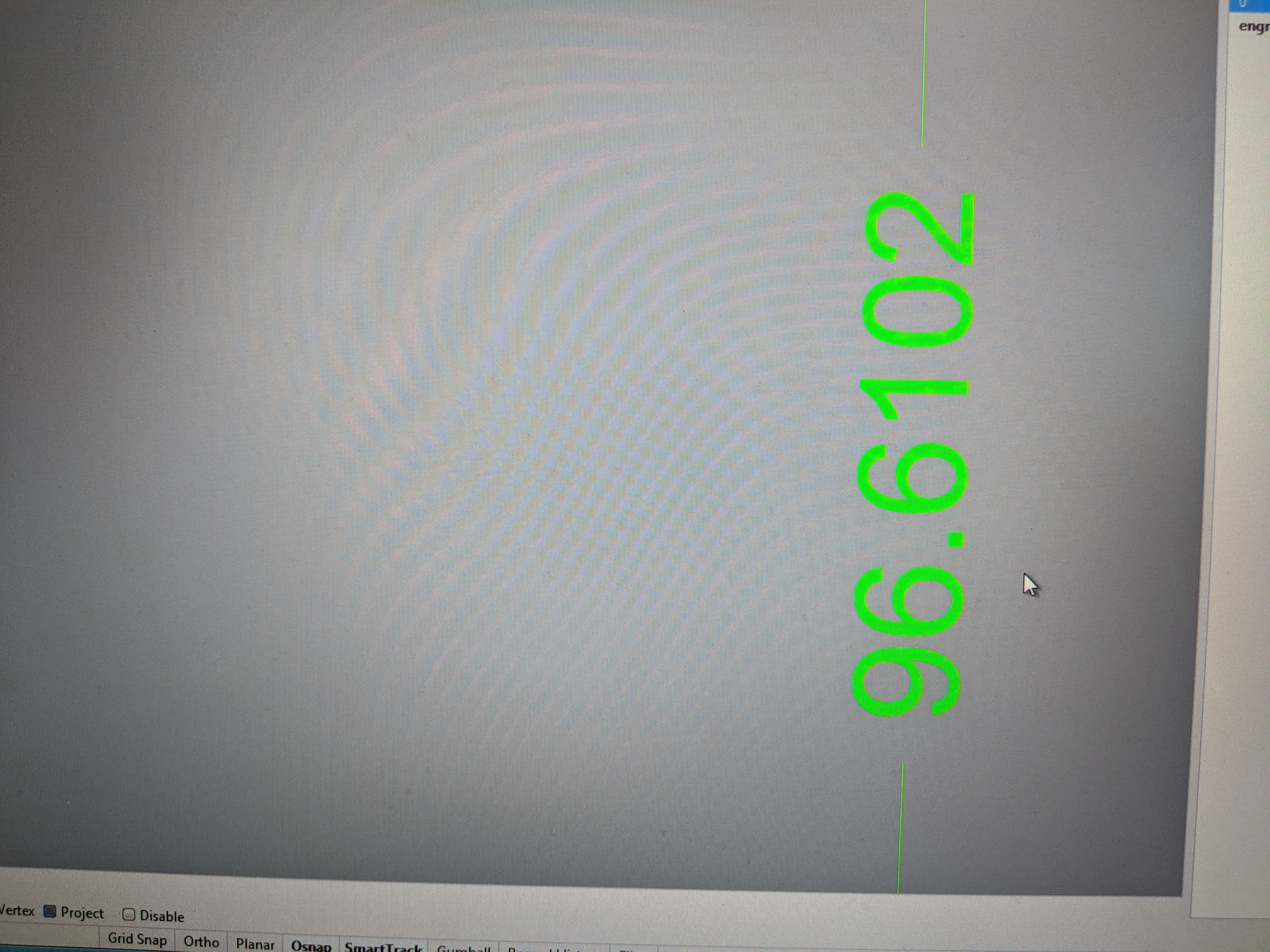

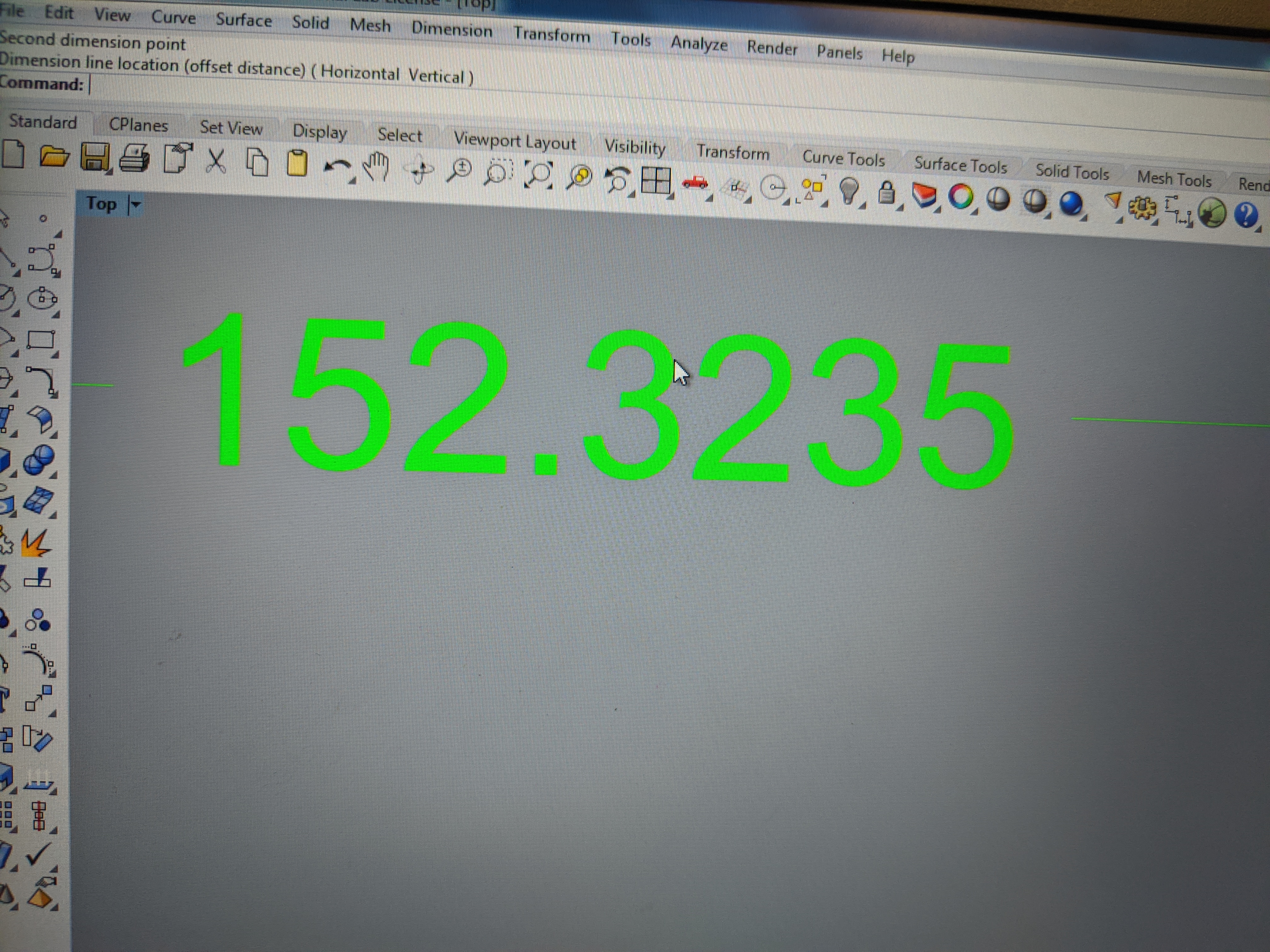

then the design should be having theses spacial dimentions on the priting page for material optimisation purpouses

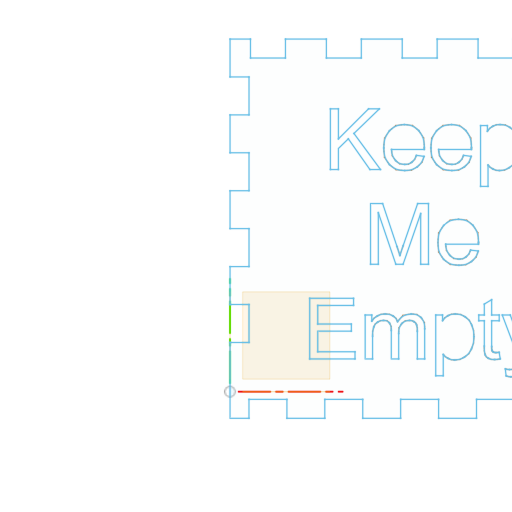

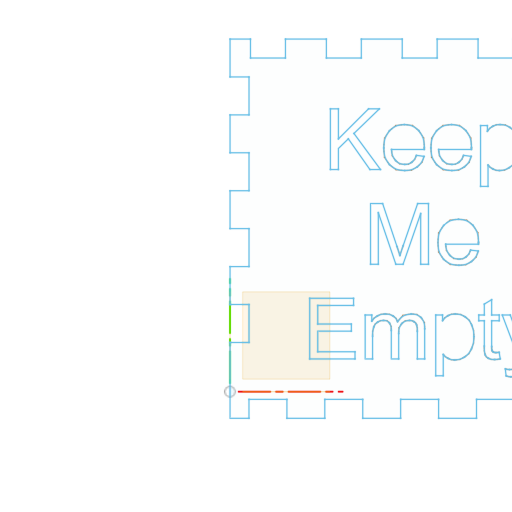

here we use the layer tool to layer out the design different specs of cutting

Here are the layers of the design

the cutting order of the design according to layers is set to be

Green: Engraving, Red: inner details, Yellow: Outer edges

the parameters of the laser cutting for engraving (MDF Material)

Power:50%, Speed:50% , Frequency: 2500Hz

the parameters of the laser cutting for cutting (MDF Material)

Power:100%, Speed:50% , Frequency: 2500Hz

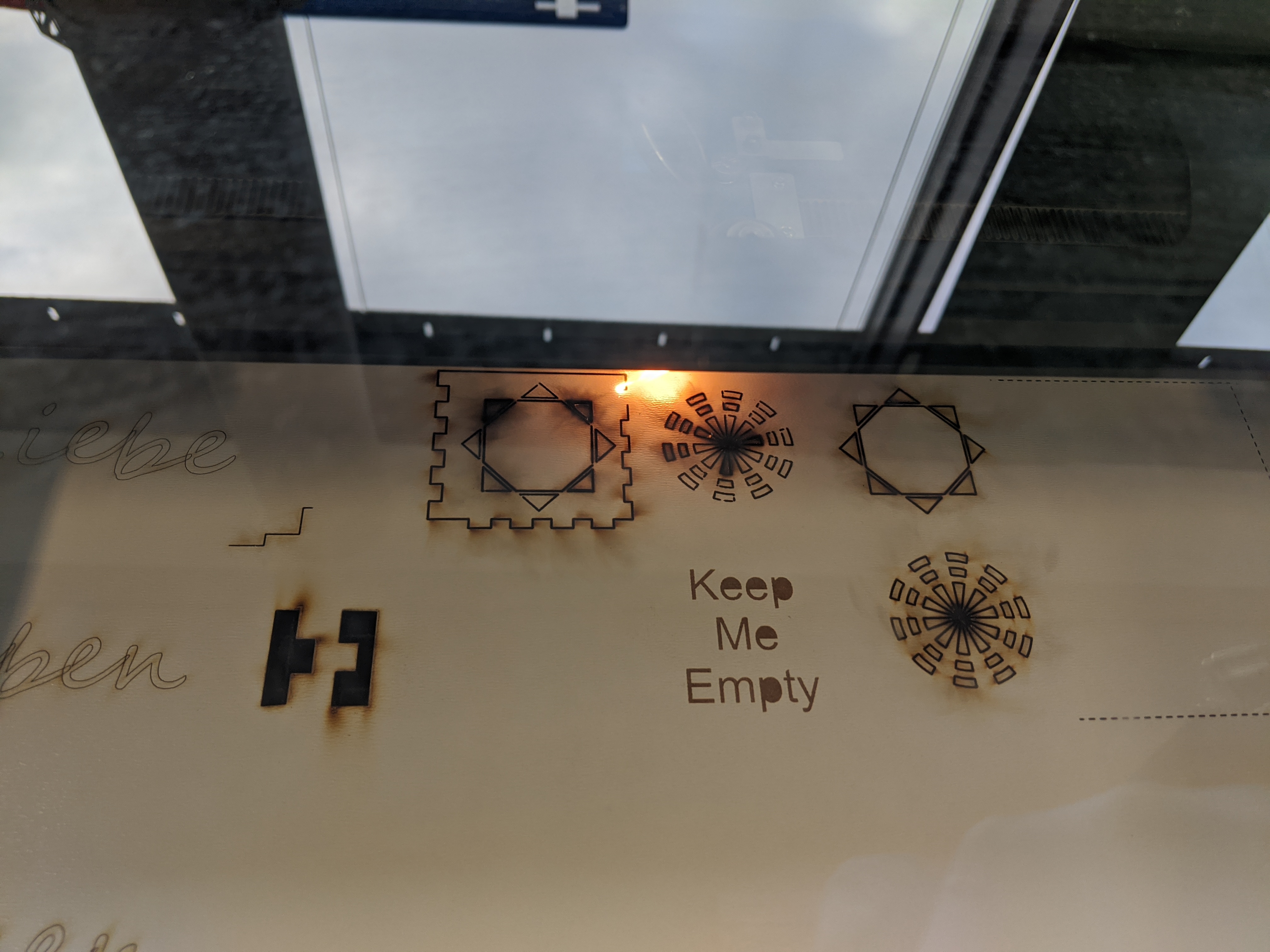

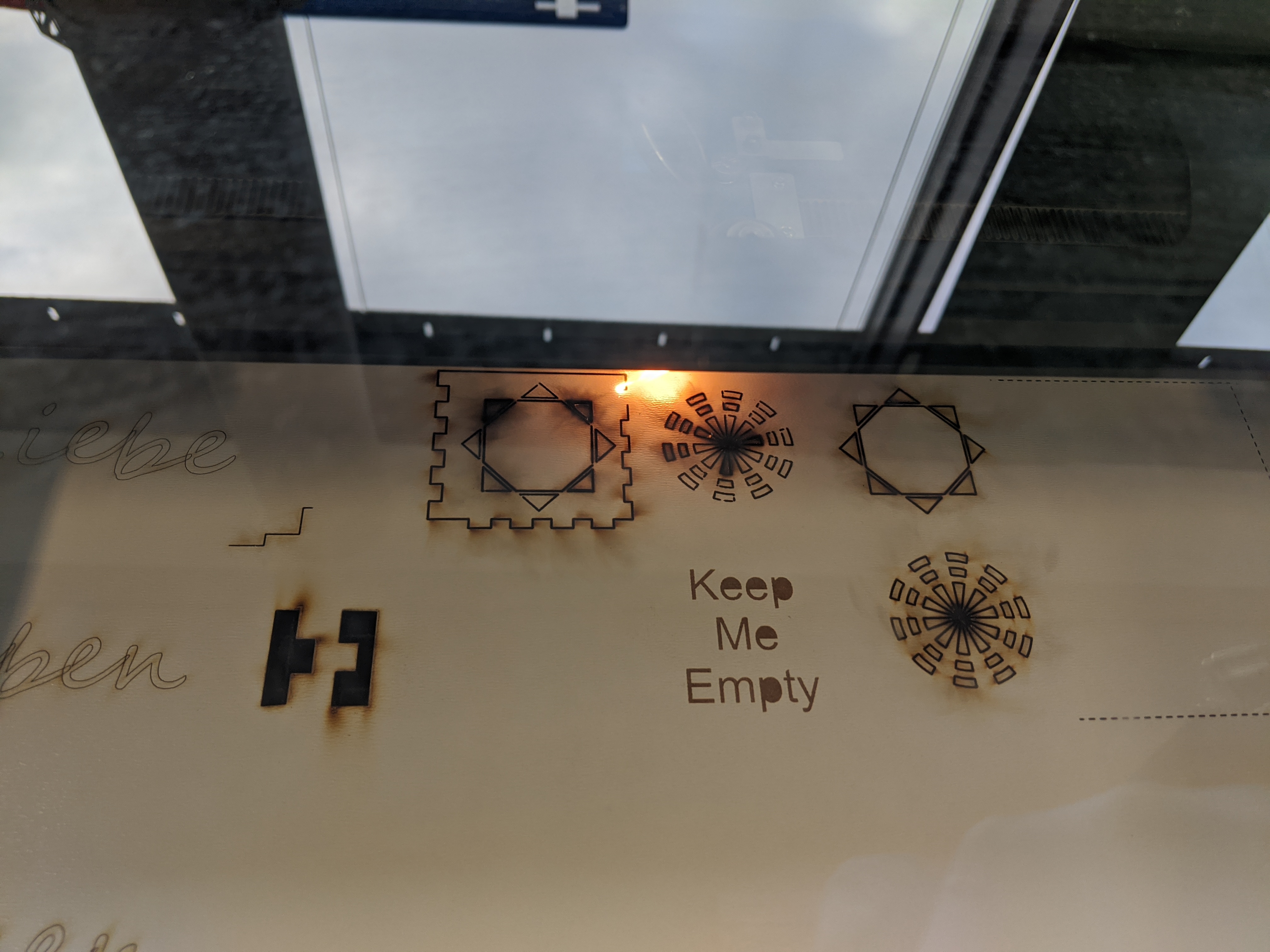

By running the printing job on the machine , we can see the progress in the following

the final print should look like this

download the f3d and dxf fles